Isostatic pressing

Isostatic pressing is to place the sample to be pressed in a high-pressure container, and use the incompressible properties of the liquid medium and the properties of uniform pressure transmission to uniformly pressurize the sample from all directions. When the liquid medium is injected into the pressure vessel through the pressure pump , according to the principles of fluid mechanics, its pressure is constant and uniformly transmitted to all directions. At this time, the pressure on the powder in the high-pressure container is uniform and consistent in all directions.

Isostatic pressing molding is the most common advanced ceramic molding process for fertile materials. By putting the powder into a flexible mold or sheath, and applying various uniform pressures to it, it can be divided into dry bag isostatic pressing and wet Bag type isostatic pressing.

During isostatic pressing, the pressure transmitted by the liquid medium is equal in all directions. The deformation of the elastic mold when it is under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the force on the green body is uniform, the density distribution is uniform, and the product performance is greatly improved.

Isostatic pressing products have the outstanding advantages of uniform structure, high density, small sintering shrinkage, low mold cost, complex shapes, slender products, large-sized products and precision-sized products.

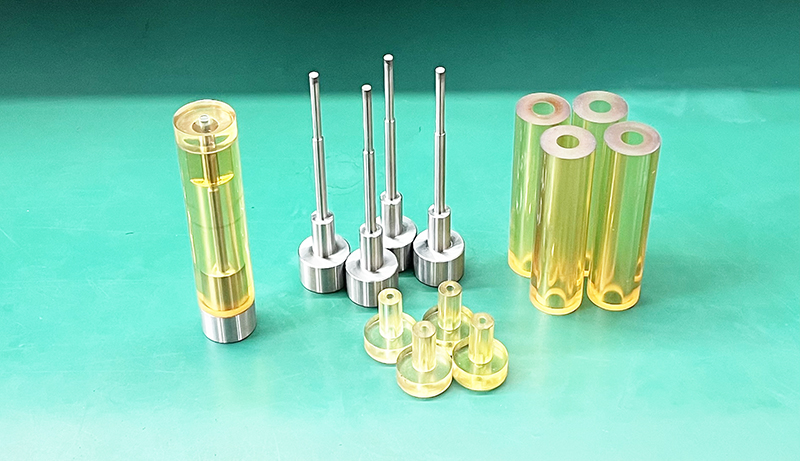

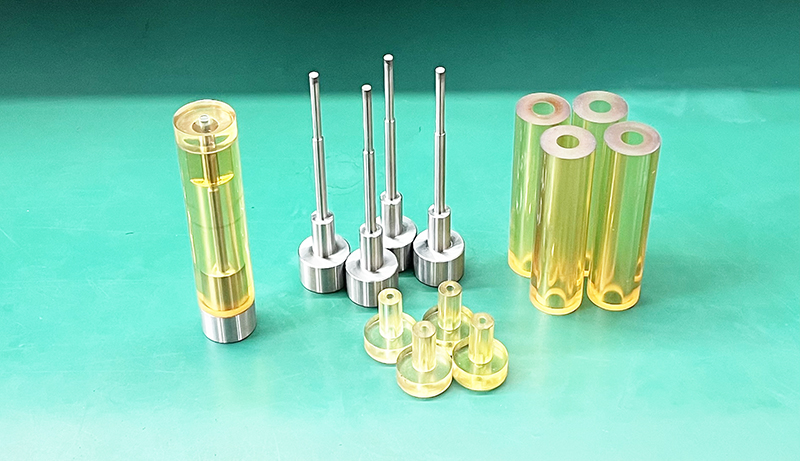

High Industry Tech provide cold isostatic pressing bags for ceramics, graphite, carbide powders forming. With rich experience of tools and equipment in CIP,we developed isostatic pressing bag for various pressing process and different powder materials.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Polyurethane Products Pu Products