Cold Isostatic Pressing

The working principle of isostatic pressing is Pascal's law: "The pressure of the medium (liquid or gas) in a closed container can be transmitted equally in all directions." Powder molding; in the past 20 years, the isostatic pressing process has been widely used in ceramic casting, atomic energy, tool manufacturing, plastics, ultra-high pressure food sterilization and graphite, ceramics, permanent magnets, high-pressure electromagnetic porcelain bottles, biological drug preparation, food preservation, High-performance materials, military and other fields.

Isostatic pressing

There are two types of isostatic pressing: cold isostatic pressing and hot isostatic pressing.

Cold isostatic pressing is divided into wet isostatic pressing and dry isostatic pressing.

Cold Isostastic Pressing (CIP)

Cold isostatic pressing has the advantage for producing parts where the high initial cost of pressing dies cannot be justified or when very large or complex compacts are needed. A variety of powders can be pressed isostatically on a commercial scale, including metals, ceramics, plastics, and composites. Pressures required for compacting range from less than 5,000 psi to more than 100,000 psi (34.5 to 690 MPa). Powders are compacted in elastomeric molds in either a wet or dry bag process.

The main structure of wet isostatic pressing is to encapsulate the pre-pressed blank in an elastic rubber mold or plastic mold, and then place it in a high-pressure container, which is filled with liquid medium. The formed body is in a high-pressure liquid, and all sides are evenly pressed, so it is called wet isostatic pressing. After pressurization, the pressure can be released, the upper cover head is opened, the mold is taken out, and the formed blank is taken out from the mold.

Dry isostatic pressing is relatively speaking, that is, the molds are not all in a high-pressure liquid medium, but semi-stationary, so that the addition of blanks and the removal of blanks are operated in a dry state. Dry isostatic pressing is quasi-isostatic pressing, and its compression molding bag can be made of nitrile rubber or ether urethane. When the dry mold bag is pressed and clamped by the upper and lower punches, the high-pressure liquid is input into the surrounding of the dry mold bag, so that the ceramic powder is formed by uniform pressure. Dry isostatic presses can be made into automated continuous presses suitable for mass production.

Applications of Cold Isostatic Pressing

1. Application of cold isostatic pressing (CIP) technology in ceramic industry

Cold isostatic pressing technology has been widely used in various fields such as daily ceramics, industrial ceramics, and special ceramics. The most promising way to manufacture ceramics with higher properties is to use the cold isostatic pressing process, in which the powder is first formed into a rough billet, which is then machined and sintered. Due to the use of forming molds made of elastic materials during cold isostatic pressing, rough blanks with complex shapes can be produced. With the addition of isotropic extremely high isostatic pressure, the press-molded blanks have sufficient In addition, it has the characteristics of small sintering shrinkage and near-net size. Therefore, the processing amount of the sintered product is significantly reduced, thereby reducing the cost of the product.

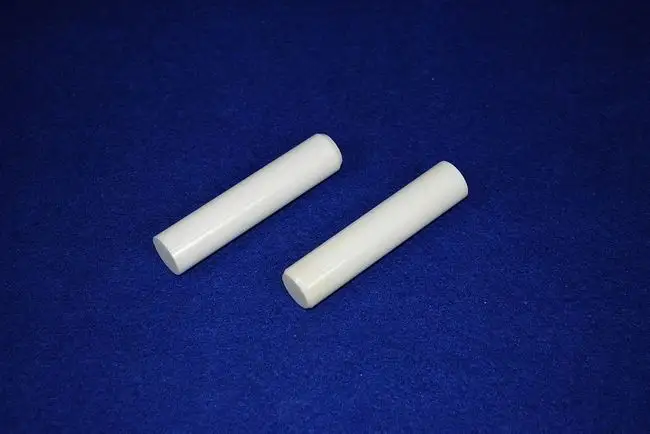

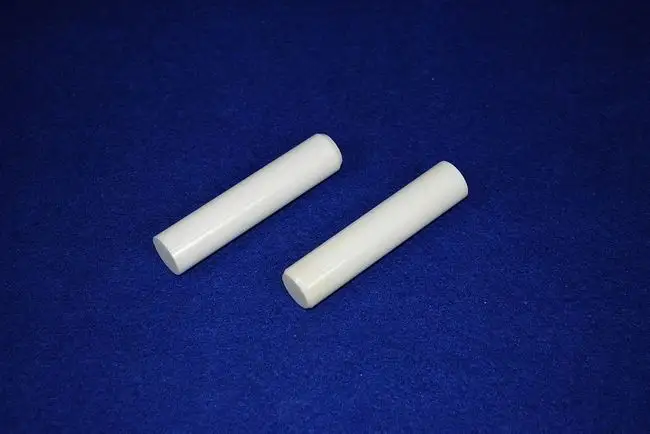

At present, from the daily ceramic products such as discs and dishes, to alumina grinding balls, alumina chemical filler balls, alumina plungers, aluminum titanate risers, ceramic radomes and other structural and functional ceramic products, spark plugs, high High-voltage electric porcelain products such as frequency porcelain sleeves and vacuum interrupters have widely adopted CIP molding technology.

2. Application of cold isostatic pressing (CIP) technology in powder metallurgy

Cold isostatic pressing technology is widely used to make cemented carbide rolls with large size, complex shape and strict performance requirements, top hammers for synthetic diamonds, cemented carbide cutting tools, etc. It is also widely used to form various powder materials with large height-diameter ratio, such as tungsten, high-speed steel, beryllium, aluminum and other rod-shaped and tubular blanks of different sizes and shapes, thus ensuring the performance of these materials and making use of powder metallurgy and cooling. The advantages of combining static pressure technology.

3. Application of cold isostatic pressing (CIP) technology in carbon graphite products

In the manufacture of large-sized graphite rods, carbon resistance elements, graphite crucibles, brushes for motors and generators, graphite heating elements, graphite tubes for nuclear reactors, and rocket nozzles and other large-sized and special-shaped parts, the production of graphite products, cold isostatic pressing Molding technology has a wide range of applications.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Molds Plastic Mold