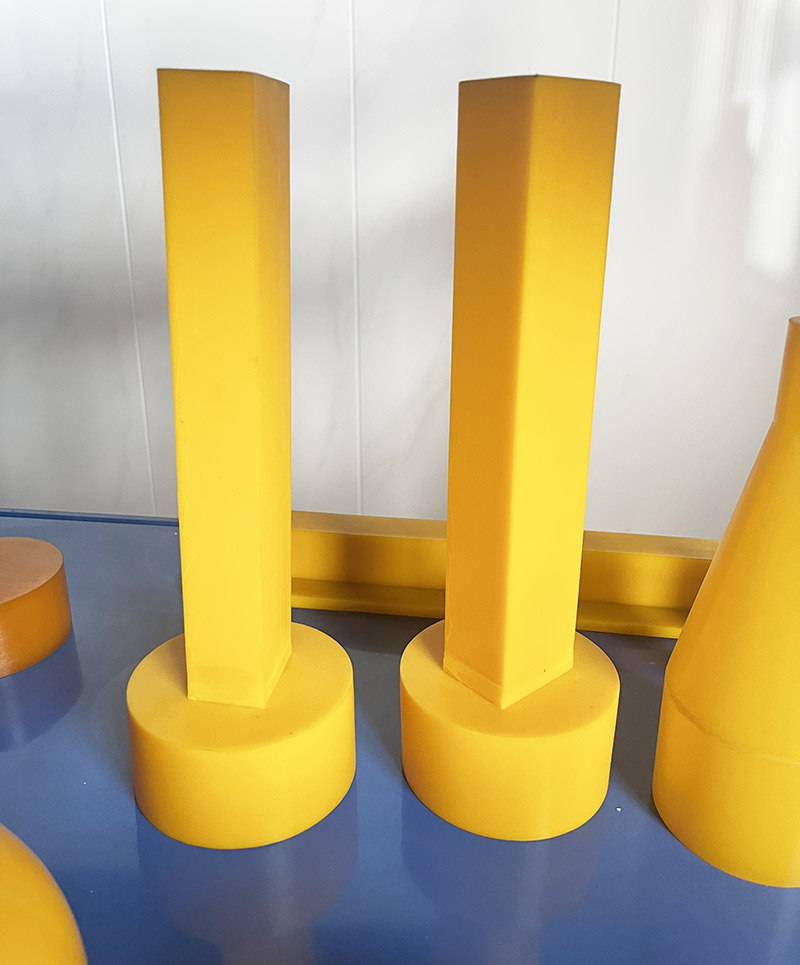

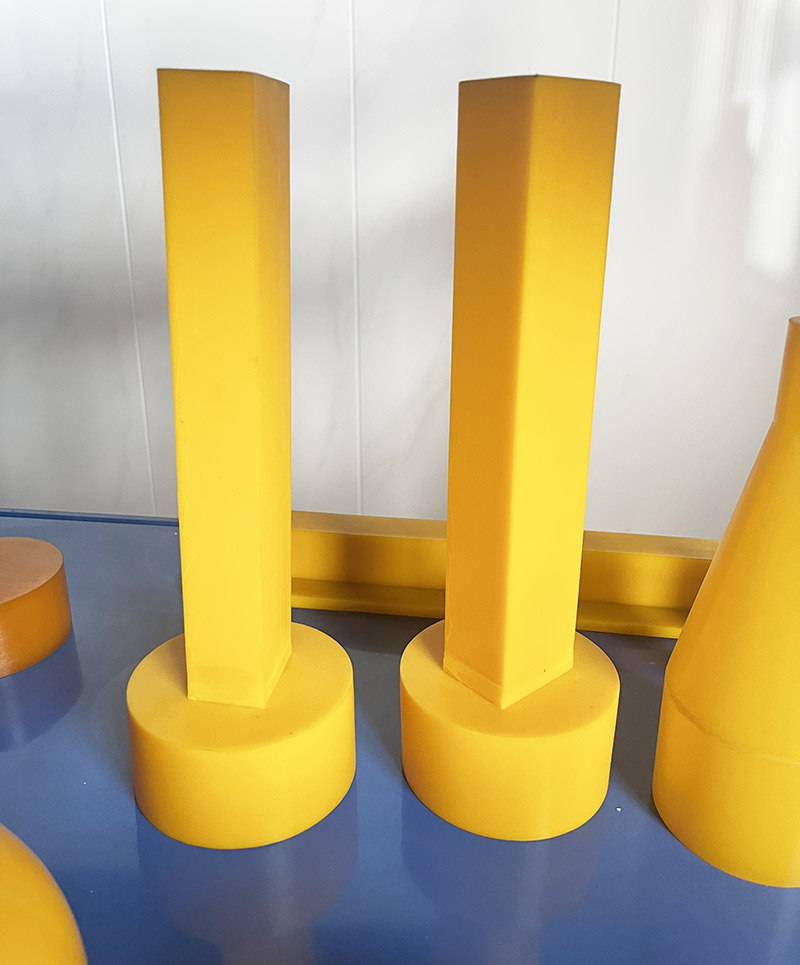

Cold Isostatic Pressing Bags/Molds/Toolings

The working principle of isostatic pressing is Pascal's law: "The pressure of the medium (liquid or gas) in a closed container can be transmitted equally in all directions." Powder molding; in the past 20 years, the isostatic pressing process has been widely used in ceramic casting, atomic energy, tool manufacturing, plastics, ultra-high pressure food sterilization and graphite, ceramics, permanent magnets, high-pressure electromagnetic porcelain bottles, biological drug preparation, food preservation, High-performance materials, military and other fields.

In this pressing process, the workpiece is required to be isolated from the pressure transfer medium and cannot make contact with the transfer medium (hydraulic oil) to cause mutual contamination. This requires isostatic dies (sleeves) that can meet the hydraulic work

Commonly used isostatic molds are polyurethane isostatic molds and rubber isostatic molds. In the traditional isostatic pressing equipment, rubber is more widely used due to its early application in isostatic pressing moulds. But in recent years, polyurethane is gradually known, because of its excellent elasticity, is replacing rubber products in various industries at an alarming rate, also including isostatic pressing equipment in isostatic pressing rubber mold.

1. Wider range of applications. Polyurethane material has a wide range of hardness, and can be made into different hardness isostatic pressing molds according to different equipment or pressing process. For example, in the pressing of large size workpieces, with a larger hardness of polyurethane material to make a rigid mold, loading material has a good support, the mold will not be deformed; in the pressing of some shaped parts, the use of low hardness of polyurethane soft mold, easy to take off the mold after pressing, easy to use. These features are not met by isostatic rubber mold.

2. Polyurethane isostatic pressing mold is more accurate. Polyurethane mold is made by casting, higher precision, more uniform material, and more obvious advantages when pressing high precision products.

3. The deformation is small and the yield is high. Polyurethane isostatic mold is made of liquid polyurethane prepolymer casting, the material is more uniform, the pressing process into a more uniform pressure transfer, will not occur bending or distortion.

4. Longer service life. Polyurethane than rubber has a better resistance to pressure, pressure after the rebound fast, small deformation, long time use of precision does not reduce. And isostatic compression rubber mold with a long time the surface is prone to oxidation and produce sticky. While polyurethane material has the ability of oxidation, after long time use or placement, the mold performance will not be reduced.

5. The surface of polyurethane mold is smoother, the surface of the finished products pressed is also smooth, post-processing is reduced, improving efficiency and reducing costs.

6. Easy to release the mold. Polyurethane has good resilience and does not stick to the material, so it can be quickly demolded after pressing, with less post-processing and high efficiency.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Polyurethane Products