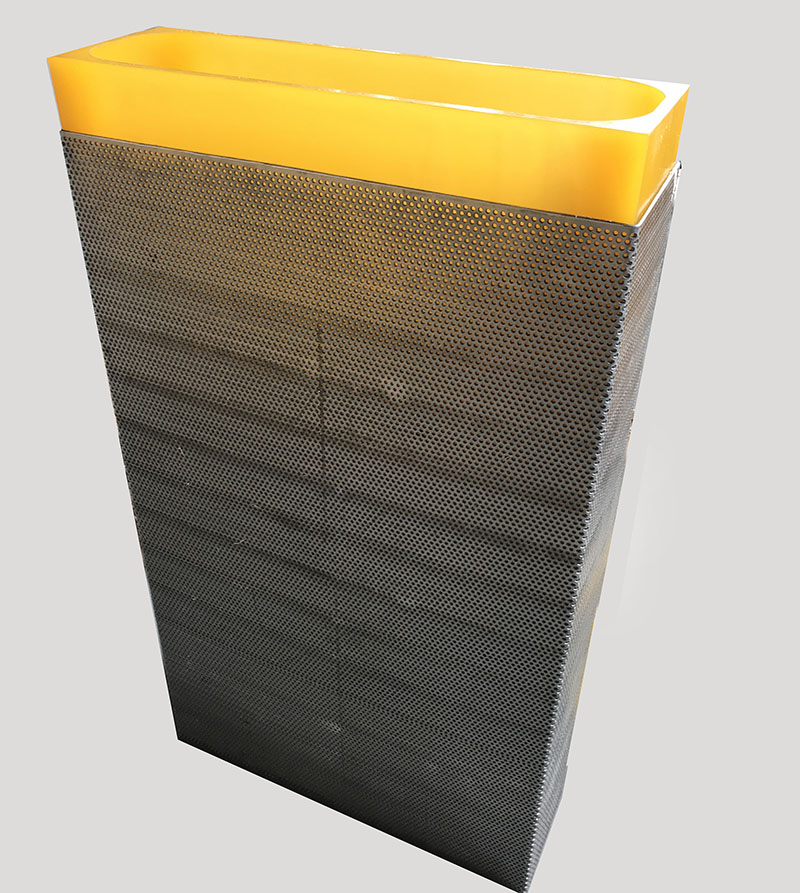

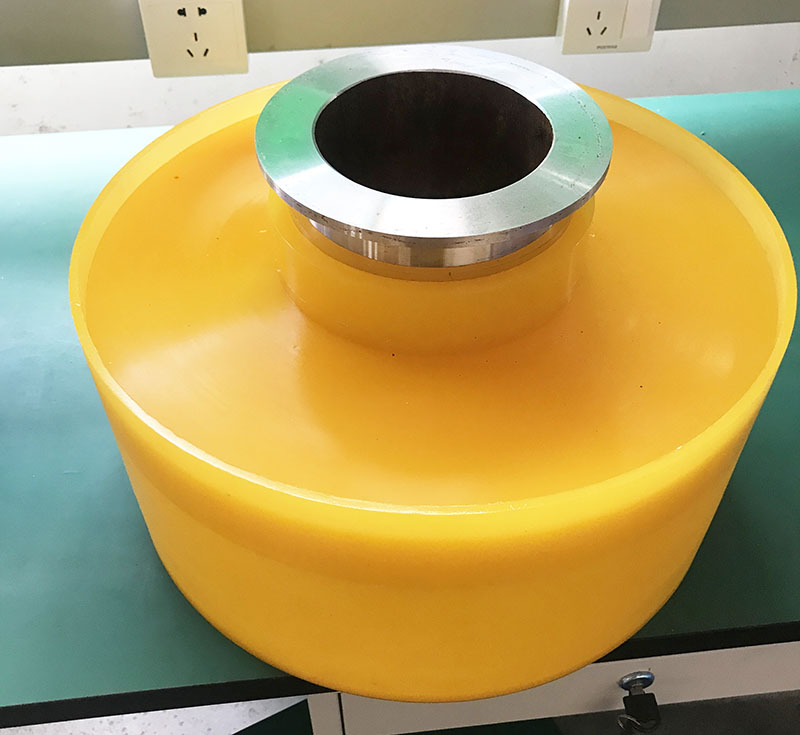

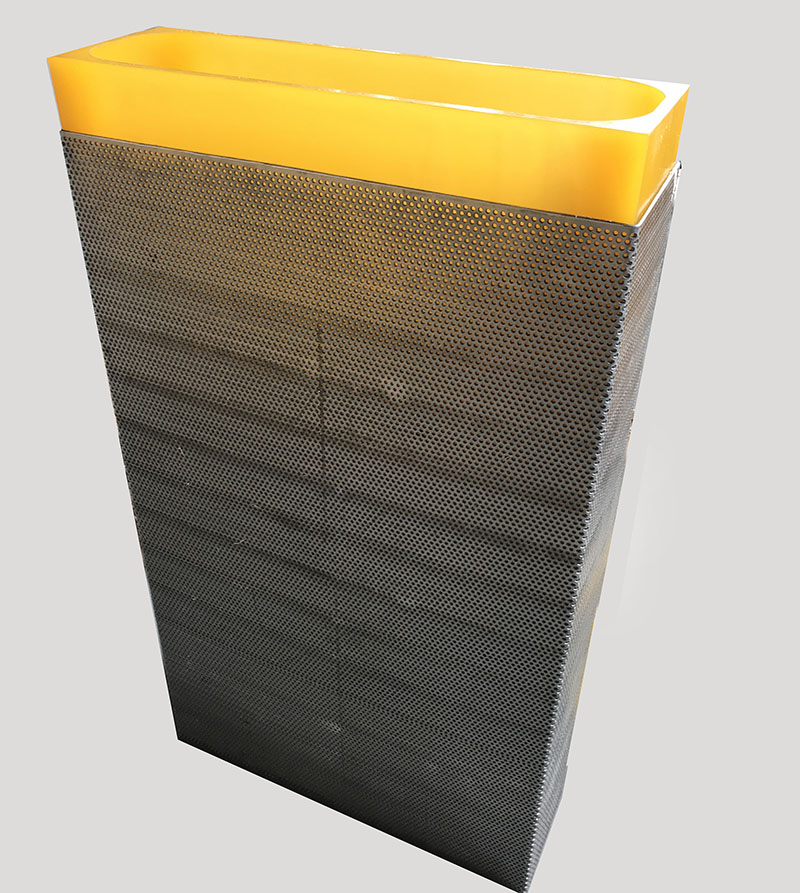

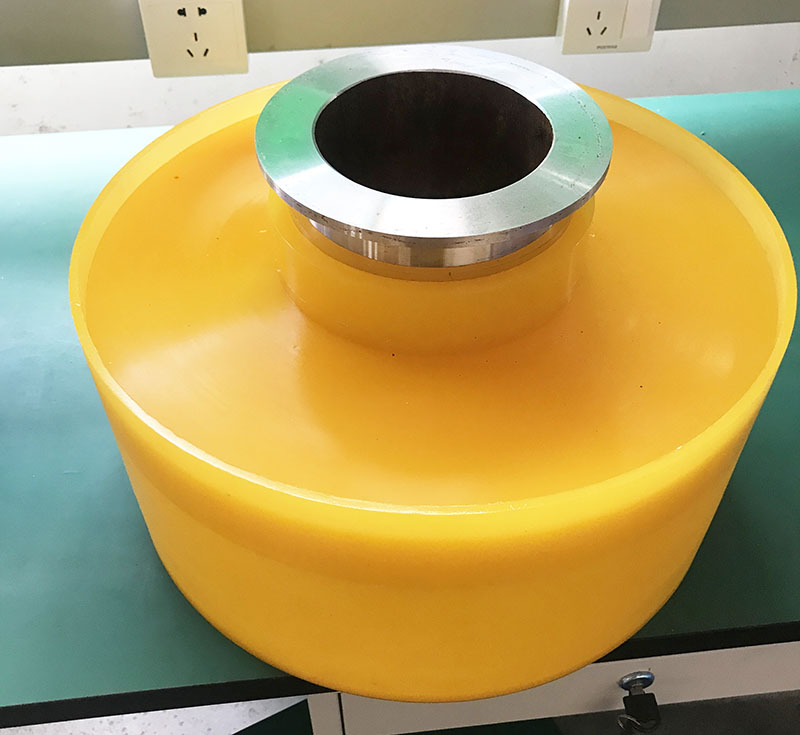

Cold isopressing bags, CIP mold design and production. There are two methods of carrying out isostatic pressing. In wet-bag isostatic pressing, powder is encased in a rubber sheath that is immersed in a liquid which transmits the pressure uniformly to the powder.

To obtain the best pressed product shape it is essential that the best powder filling system be used to ensure an even powder density across the filling area and throughout the length of the cavity. unique Volumetric Powder Filling System ensures these characteristics are achieved thus enabling the highest possible pressed compact accuracy and consistency even on very thin walled tubes. The flowability of the powder determines the type of powder filled used. Where flowability is not an issue the Isoform’s Volumetric powder filling system is always preferred.

Contact High Industry Tech

Tel: +86-15905285887 Mr. Bluce Yan

cip@highindustryco.com

Wechat/QQ ID: 15905285887

Skype ID: bluce_yan