Classification of Isostatic Pressing

Isostatic forming is to place the specimen to be pressed in a high-pressure vessel, and use the nature of the liquid medium not to shrink and the nature of uniform transfer of pressure from all directions to uniformly pressurize the specimen. When the liquid medium is injected into the pressure vessel through the pressure pump, the pressure is constant and uniformly transferred to all directions according to the principle of fluid mechanics.

Classification of isostatic pressing:

Wet isostatic pressing, in which the pre-pressed blank is encapsulated in an elastic plastic or rubber mold, sealed and placed in a high-pressure cylinder, and the blank is pressed into shape through the transfer of liquid.

Dry isostatic pressing, the elastic mold is semi-fixed, not immersed in liquid medium, but sealed by upper and lower pistons. The pressure pump injects the liquid medium between the high-pressure cylinder and the pressurized rubber, and the pressure is transferred through the liquid and the pressurized rubber to make the blank pressed into shape.

Cold isostatic pressure technology, is at room temperature, usually month rubber or plastic for the envelope mold material, with liquid as the pressure medium mainly with a powder material molding, for further sintering, calcination or process to provide a blank. The general use pressure is 100~630MPa.

Temperature isostatic pressure technology, pressing temperature is generally under 80 ~ 120 ℃, but also under 250 ~ 450 ℃, the use of special liquid or gas transfer pressure, the use of pressure for about 300MPa. Mainly used for powder materials in room temperature conditions can not be formed graphite, polyamide, rubber materials, etc.

Hot isostatic pressing technology HIP , is a kind of process technology to make the material undergo at high temperature and high pressure at the same time, it is not only used for the solidification of powder body. It is used not only for the solidification of powders, but also for the elimination of workpieces and the production of complex shaped parts. In by, generally use xenon, ammonia and other inert gas as the pressure transfer medium, the cladding material is usually used metal or glass. Operating temperature is generally 1000 ~ 2200 ℃, the working pressure is often 100 ~ 200MPa.

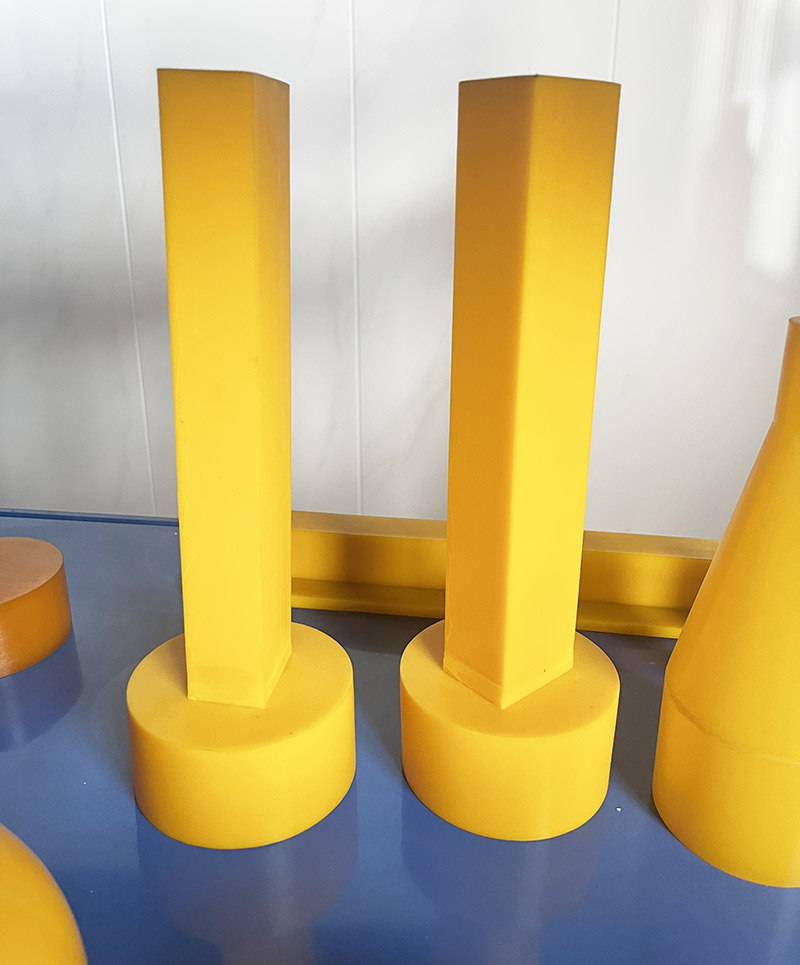

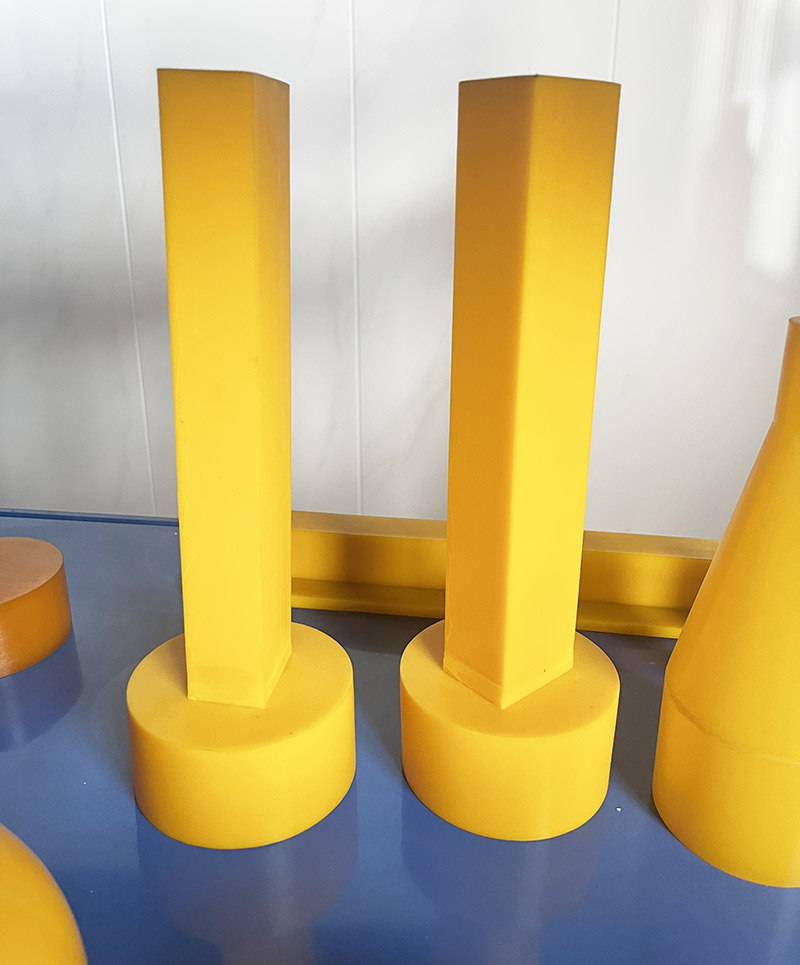

Cold Isostatic Pressing bags,molds,toolings

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com