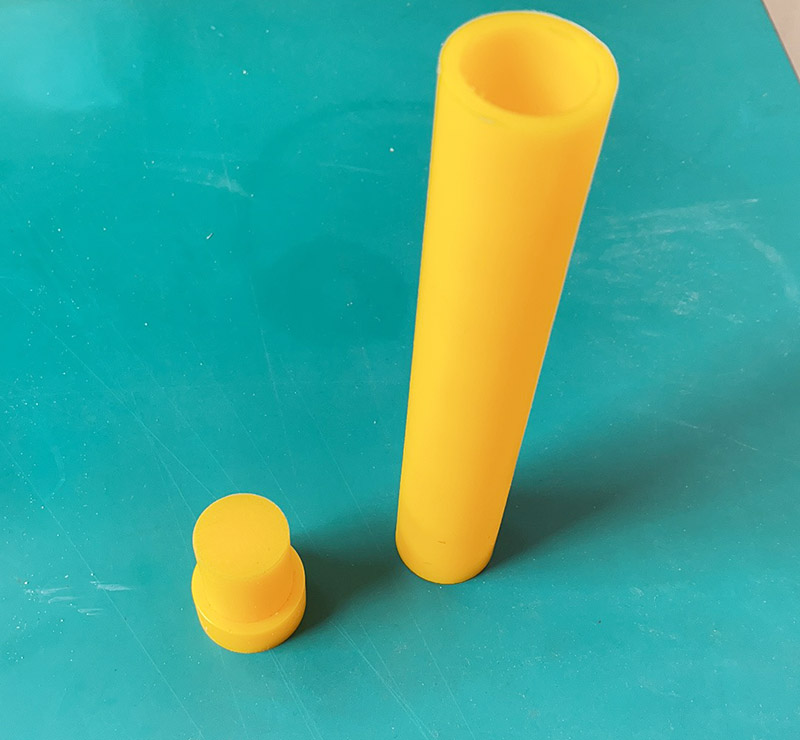

Elastomer CIP mold, polyurethane rubber material isostatic press bags, elastic mold for isopressing

Categories: Wet bag CIP mold

Application: elastomer CIP mold, polyurethane rubber material isostatic press bags, elastic mold for isopressing powder forming

InquiryMain description:

Elastomer CIP mold, polyurethane rubber material isostatic press bags, elastic mold for isopressing powder forming, To reduce the load in the polyurethane isostatic pressing, the diameter of the container or D of the polyurethane mold should be as small as possible. This means that the thickness of the rubber should be small in comparison with the size of the cavity. To understand the effect of rH and rD on the shape or dimensions and density distribution of the compact, we carried out simulation.