Cold Isostatic Pressing

Cold isostatic pressing technology is usually used rubber or plastic as the mold material at room temperature, and liquid as the pressure medium. It is mainly used for powder material molding to provide blanks for further sintering, forging or hot isostatic pressing. body. The general operating pressure is 100~630MPa. Cold isostatic pressing technology is widely used to make cemented carbide rolls with large size, complex shape and strict performance requirements, top hammers for synthetic diamond, cemented carbide cutting tools, etc. It is also widely used to form various powder materials with large height-diameter ratio, such as tungsten, high-speed steel, beryllium, aluminum and other rod-shaped and tubular blanks of different sizes and shapes, thus ensuring the performance of these materials and giving full play to powder metallurgy and cooling. The advantages of combining static pressure technology.

Cold isostatic pressing is divided into wet bag method and dry bag method.

Wet (wet bag method) isostatic pressing: The blank (or pre-pressed in advance) is encapsulated in an elastic plastic or rubber mold, sealed and placed in a high-pressure cylinder, and the blank is pressed and formed by liquid transfer. This method can change the shape and size of the plastic wrap, and the product is very flexible and suitable for small-scale production. However, manual bagging and unloading operations are required every time, and the production efficiency is not high. This method is mainly used for the production of large and special-shaped parts.

Dry (dry bag method) isostatic pressing: The elastic mold is semi-fixed, not immersed in a liquid medium, but sealed by upper and lower pistons. The pressure pump injects the liquid medium between the high-pressure cylinder and the pressurized rubber, and transmits the pressure through the liquid and the pressurized rubber to press the green body to form. This method can be operated continuously, that is, the upper cover of the mold is opened, the material is loaded, and then the upper cover is closed to press the molding. The operation cycle is short, and it is suitable for batch production; at present, this method is used for continuous industrial production of daily-use porcelain plates, dishes and medium-sized alumina grinding balls. The dry bag method has a short operating cycle and is suitable for batch production, but the product specification is limited because the pressurized plastic mold cannot be changed frequently.

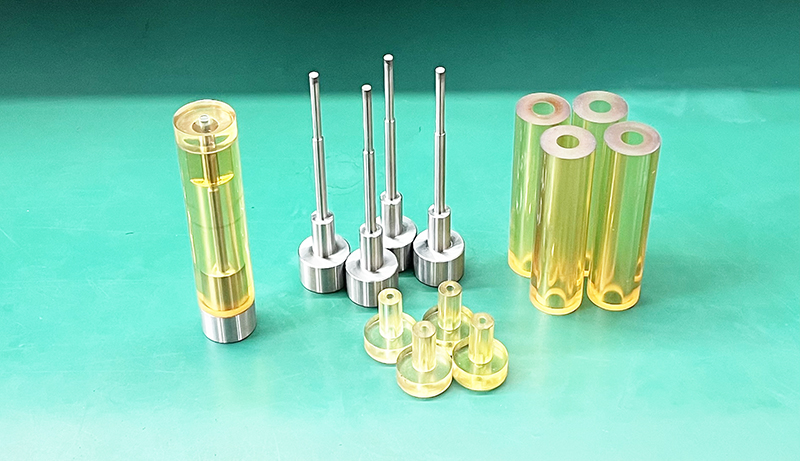

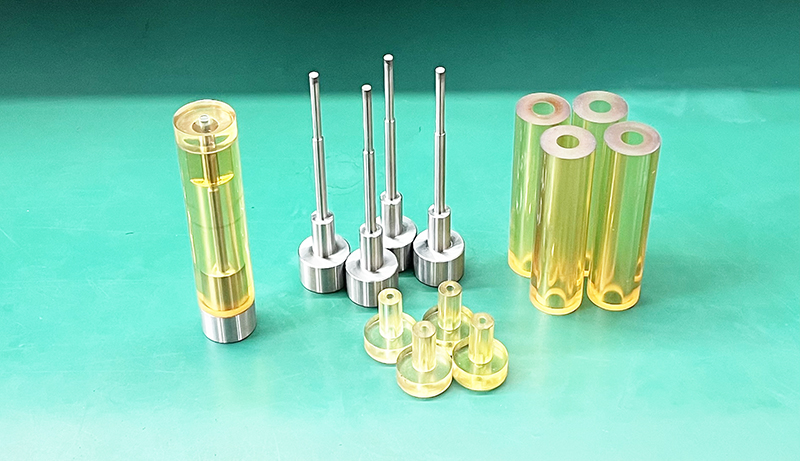

Some Isostatic Pressing Bags we made:

Wet- bag Isostatic Pressing Mold/Bag/ Tooling

Dry-bag Isostatic Pressing Bag/Mold/Tooling

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com