What is a Graphite Crucible?

A graphite crucible is a container used for melting and casting non-ferrous, non-iron metals such as gold, silver, aluminum, and brass. Their thermal conductivity, high temperature resistance, small thermal expansion coefficient for high temperature applications, and anti strain properties to rapid heating and cooling make graphite crucibles an ideal metal casting tool.. They are resistant to the effects of acids and alkaline solutions and have excellent chemical stability.

Graphite is produced from natural graphite, a naturally occurring crystalline form of carbon and is manufactured by combining graphite with fire resistant clay or carbon dioxide.

Synthetic graphite is made by processing petroleum pitch and petroleum coke, which are byproducts of the oil refining process. It has a purer high fixed carbon content with very few impurities and a low sulfur content.

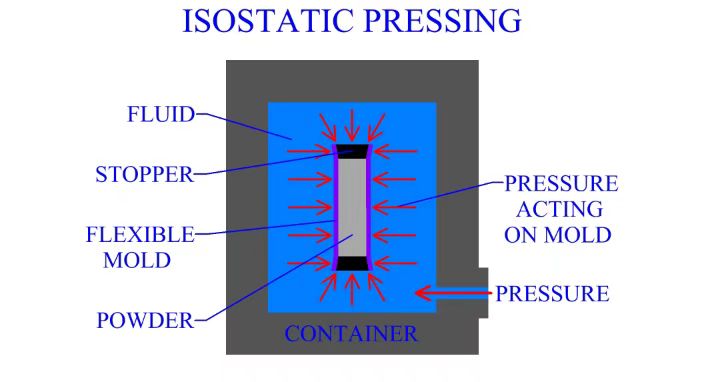

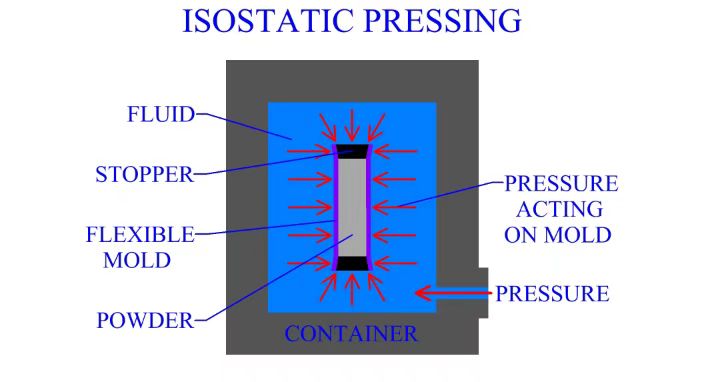

Isostatic Pressing

The molding process forms graphite crucibles by isostatic pressure using powder metallurgy. Equal pressure is applied to the powder to uniformly compact it to the proper density and microstructure. The process can be performed cold or hot. Graphite crucibles formed by this method have excellent properties that are uniformly distributed throughout the entire mass without a grain direction, or are anisotropic.

The high density and small particle size of this type of crucible creates a very strong machinable graphite tool with resistance to high temperatures in controlled environments, electro-conductivity, and self lubricating properties.

The advantages of Isostatically Pressed Crucibles are:

· Wide range of qualities

· Wide range of crucibles sizes

· Smooth internal surface giving a reduction of inclusions

· Consistent material properties throughout crucible

· Defect free- no casting bubbles etc

· Uniform density throughout the product improving its resistance to thermal stress

The CIP mold for Isostatic Pressing Graphite:

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com