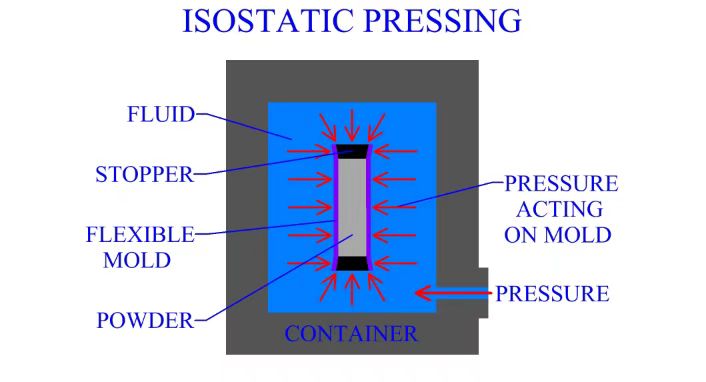

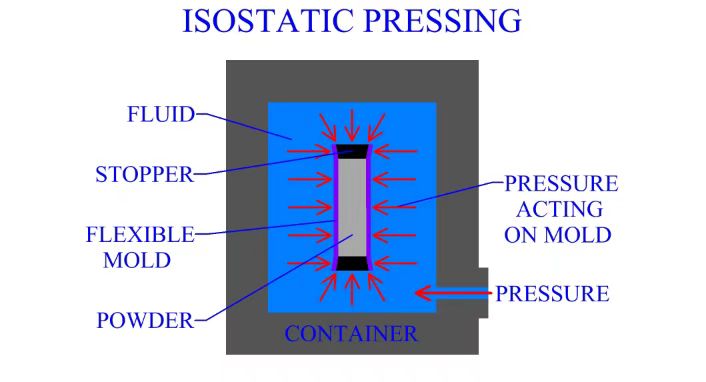

Basic Concepts of Isostatic Pressing Technology

In simple terms, isostatic pressing technology is a technology that applies equal pressure to the surface-closed material from all directions. In powder metallurgy, this technology mainly acts on the consolidation and forming of powder materials. After practice, the application of isostatic pressing technology in powder metallurgy has obvious technical advantages. First, this uniform pressure can densify powder metallurgy materials and make them have higher strength; secondly, isostatic pressing technology can Defects within the material are reduced or even eliminated; finally, the technology can also act as an adhesive, bonding dissimilar materials together at high temperatures. Due to the obvious advantages of isostatic pressing technology in the field of powder metallurgy, this technology has been widely used in the field of materials science and engineering. So far, the products processed by isostatic pressing technology can be applied to industries with strict material requirements such as aerospace, mining machinery, synthetic diamond, petrochemical and atomic energy. Isostatic pressing technology can directly form geometrically loaded alloy parts under certain conditions, and the products produced by isostatic pressing powder metallurgy technology have better physical and mechanical properties. The application of isostatic pressing technology enables some powder metallurgy material products to replace casting metallurgical materials in terms of performance and life, thereby reducing the use of casting technology and having a certain environmental protection effect.

Isostatic graphite is an ultra-fine grain graphite used for applications where the mechanical properties of other fine grain graphites are inadequate.

The term "isostatic graphite" stands for isostatically molded graphite. This means that the raw material mixture is compressed into rectangular or round blocks in a so called Cold-Isostatic-Press (CIP).

Compared to other technologies such as extrusion or vibration molding, this technology can produce the most isotropic form of artificial graphite. In addition, isostatic graphite generally tends to have the smallest grain sizes of all artificial graphites.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com