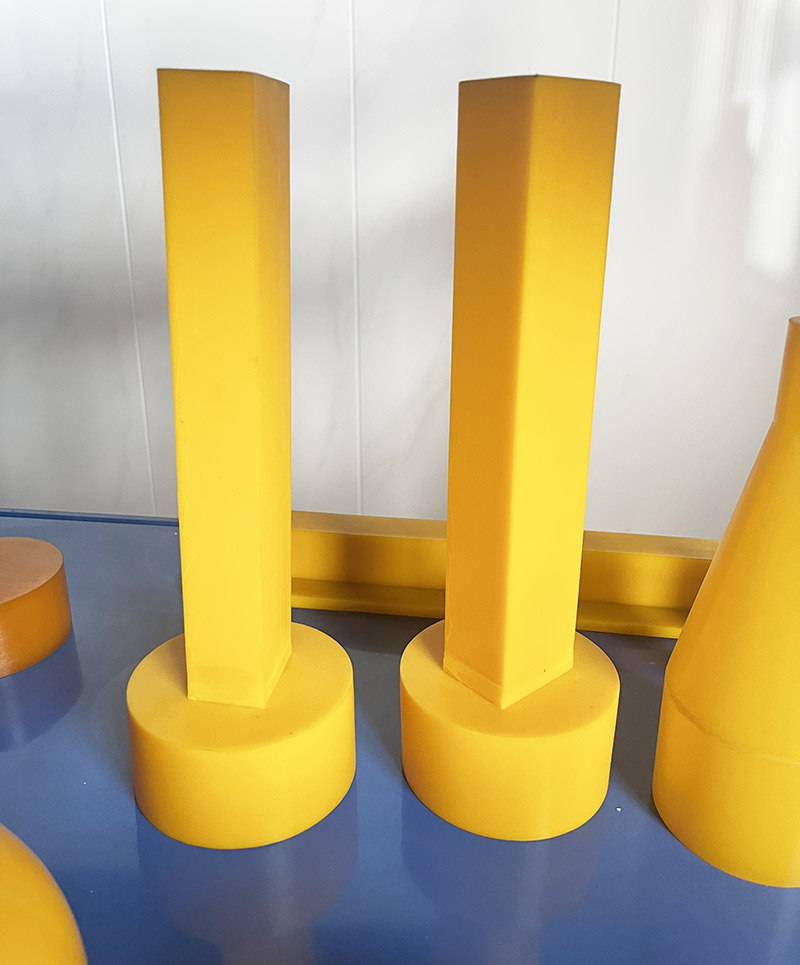

Characteristics of Isostatic Pressing Process

Categories: Isopressing mold

Application: Characteristics of Isostatic Pressing Process

InquiryMain description:

The isostatic pressing process is to place the product in a closed container filled with liquid, and by applying equal pressure to each surface of the product, in a closed environment, the density of the product is increased and the desired shape is obtained. With the advancement of science and technology, the isostatic pressing process is more and more widely used in the molding of high temperature refractory materials, ceramics, cemented carbide, rare earth permanent magnets, carbon materials, and rare metal powders.