Cold Isostatic Pressing- CIP

Cold isostatic pressing technology, (Cold Isostatic Pressing, referred to as CIP) is at room temperature, usually with rubber or plastic as the mold material, with liquid as the pressure medium is mainly used for powder material molding, for further sintering, forging or The hot isostatic pressing process provides the green body. The general operating pressure is 100~630MPa.

Hot Isostatic Pressing (HIP)

Hot isostatic pressing is a manufacturing process which utilizes elevated temperature and isostatic gas pressure to eliminate porosity and increase density in metals, ceramics, polymers, and composite materials. This improves the material's mechanical properties and potentially workability. Primary applications are the elimination of microshrinkage in castings, the consolidation of powders and diffusion bonding, often referred to as cladding. Hot isostatic pressing is also used as part of a sintering (powder metallurgy) process, for pressure-assisted brazing and for fabrication of metal matrix composites.

HIP vs Cold Isostatic Pressing (CIP): What’s the Difference

Cold isostatic pressing (CIP) is similar to HIP in that both material treatment processes use pressure to improve the physical properties of a material. As the name suggests, however, CIP is performed at lower temperatures than its HIP counterpart. According to the European Powder Metallurgy Association (EPMA), HIP is typically performed at roughly 1,650 to 2,300 degrees Fahrenheit. In comparison, CIP is performed at or near room temperature.

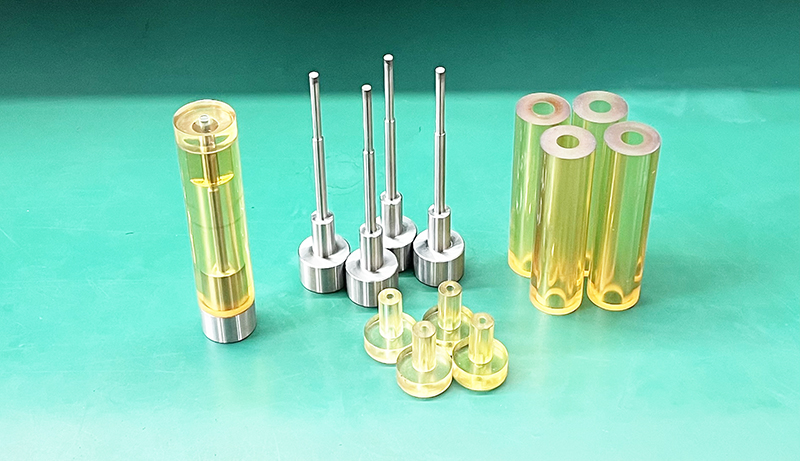

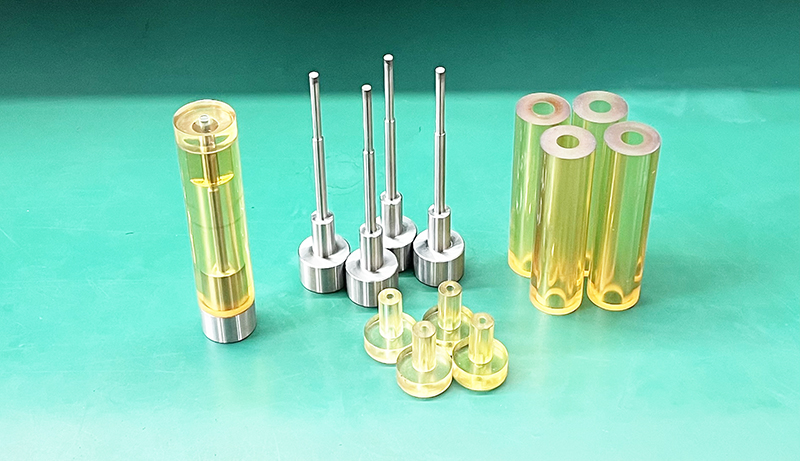

Some CIP bags:

Cylindrical CIP bags for PTFE

Crucible CIP bags

Square CIP bags for Graphte

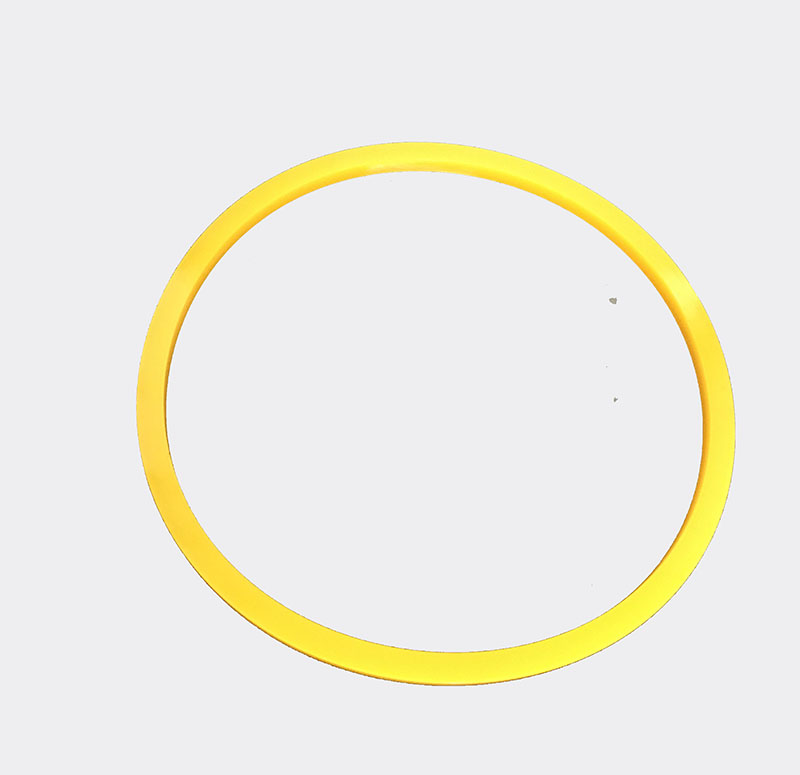

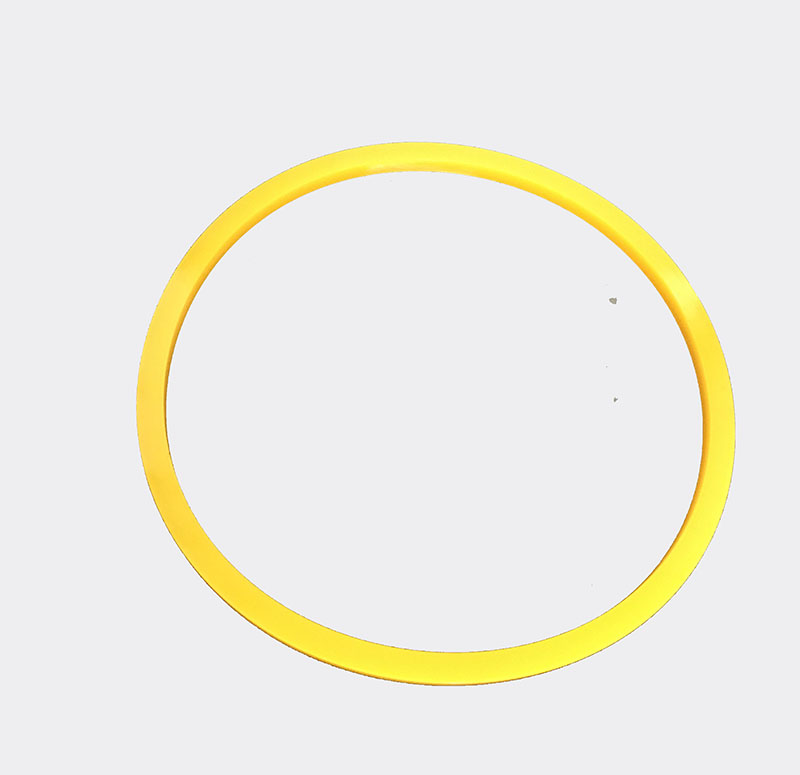

Round CIP bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com