Cold Isostatic Pressing - CIP

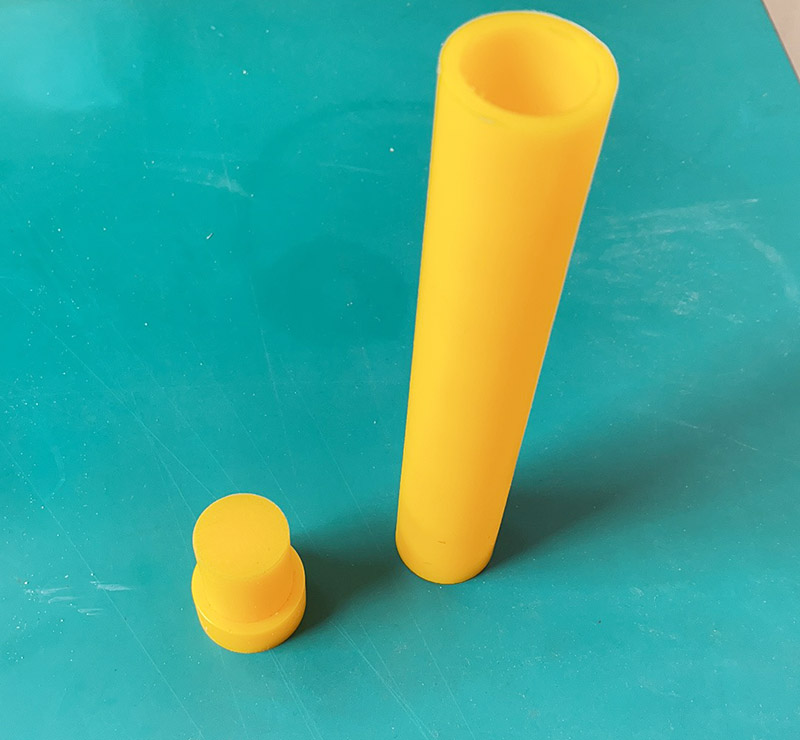

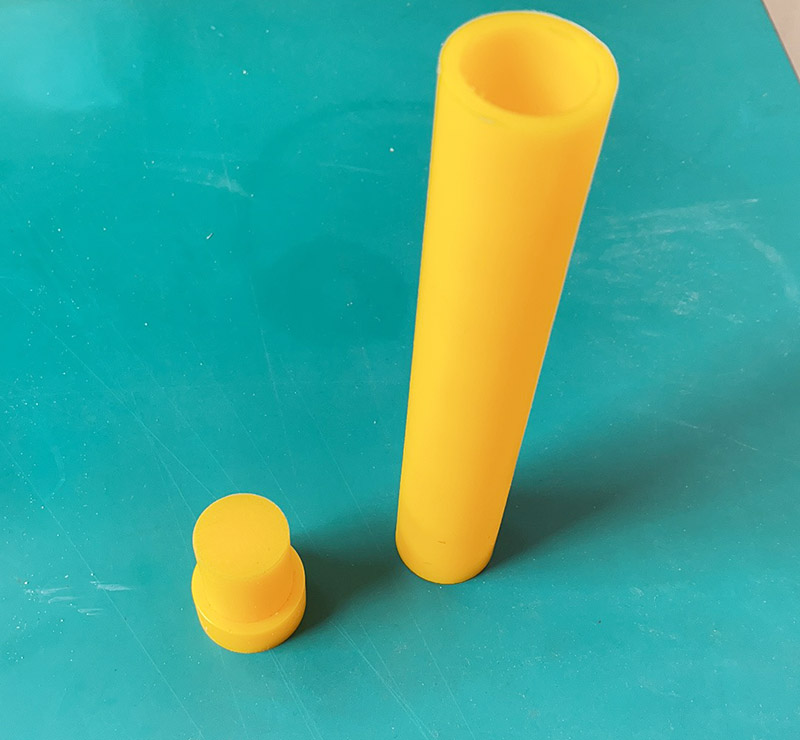

Cold isostatic pressing technology, (Cold Isostatic Pressing, referred to as CIP) is at room temperature, usually with rubber or plastic as the mold material, with liquid as the pressure medium is mainly used for powder material molding, for further sintering, forging or The hot isostatic pressing process provides the green body. The general operating pressure is 100~630MPa.

Cold isostatic presses (CIP) that function at room temperature and hot isostatic presses (HIP) that function at elevated temperatures. Applications for these processes include consolidation of powdered metals, ceramics, carbides, composites, pharmaceuticals, carbon / graphite, ferrites, explosives, chemicals, foods, nuclear fuel or other materials into compact shapes.

Cold pressed metals or ceramic powder compacts may require additional processing, such as sintering, to provide a finished part. Cold isostatic pressing is a compaction process by which powders are turned into include refractory nozzles, blocks, and crucibles; cemented carbides, isotropic graphite, ceramic insulators, tubes for special chemical applications, ferrites, metal filters, preforms, and plastic tubes and rods. The powder material is placed within a mold, then placed into the CIP processing chamber. A liquid medium, often an oil-water mixture, is pumped in and pressurized on all sides to create a uniform product.

The pressure with a CIP chamber may reach as high as 100,000 psi.CIP applications Advantages of cold isostatic presses include the creation of product with uniform density, which leads to a reduction of internal stresses, eliminating cracks, strains and laminations. They also press products that have a higher “green strength” which allows for close tolerances, complex shapes, and better machinability. In addition, the CIP process is relatively inexpensive. Separate styles of cold isostatic presses are available for both industrial and laboratory applications.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com