Features of Isostatic Press Molding

Categories: CIP powder forming bag mold

Application: Features of Isostatic Press Molding

InquiryMain description:

Features of Isostatic Press Molding

Features of Isostatic Press Molding

Features of isostatic press molding

(1)The pressure in the working vessel of the isostatic brick press is high, up to 400MPa or higher, and the pressure in all directions in the vessel is consistent, so the pressure on all parts of the clay is uniform, and the density of the formed plain billet is high and uniform, thus reducing the deformation and shrinkage of the billet during firing, and not causing firing cracks due to stresses arising from density differences.

(2) The forming pressure of the isostatic press can be easily adjusted, and the operation is simple during pressurization, but the decompression and post-processing of the billet will be carried out after pressurization.

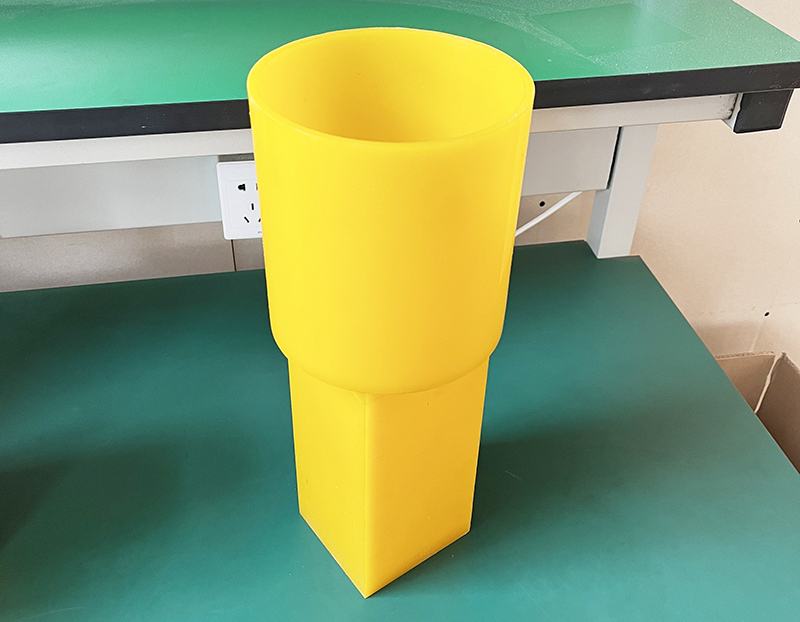

(3) Molds for molding are made of rubber or plastic, which are easy and inexpensive to manufacture and can be used repeatedly.

(4) No or less temporary binding agent can be used in the blank.

(5) Isostatic pressing method can press the complex shape of large pieces and elongated products that cannot be formed by general molding methods.