Isostatic Molding

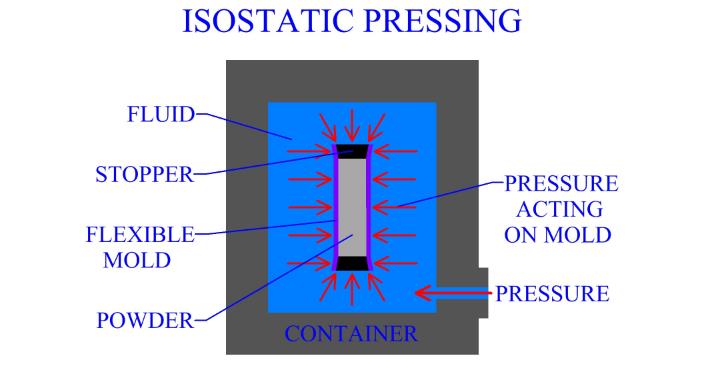

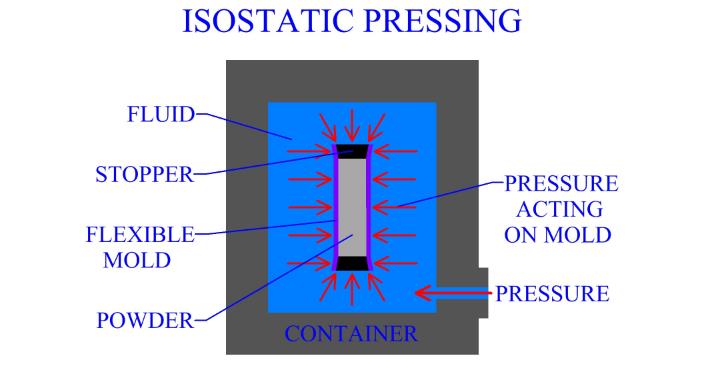

Isostatic molding is a unique process where molding pressures are applied evenly in all directions around the part being made. This differs from compression molding, which has pressure applied in only one direction. Isostatic molding lends itself nicely to making odd shapes such as cups and buckets. An isostatically molded part is made to near net shape. Because the part is molded to near net shape, significantly less material would be used as opposed to the more standard use of blocks and cylinders. After molding, the part would be suitable for final machining.

Tapered sleeves and closed end cylinders are common shapes that are often molded isostatically. Unlike extruded and compression-molded parts, materials isostatically molded will have highly consistent material properties. This method is followed for making polytetrafluoroethylene products.

The PTFE surface formed during isostatic molding depends on the type of surface against which it is formed. The mandrels are usually made of polished metal and yield a smooth preform surface. The more polished the mandrel, the smoother the surface of the preform. A flexible bag forms a surface that is normally not smooth because the bag tends to conform to the individual particles of resin. A softer bag tends to form less smooth surfaces than a harder bag. Surface finish is important in a number of applications. For instance, it is desirable to have liners with smooth surfaces for chemical processing service because of the need to minimize buildup on the process surfaces. These liners are usually made by inside mandrel isostatic molding where the interior part surface is formed against a polished metal mandrel.