Cold Isostatic Pressing

Cold isostatic pressing is a manufacturing process used for compaction of powders. The process is similar to pressing using cupped hands for making snow balls.

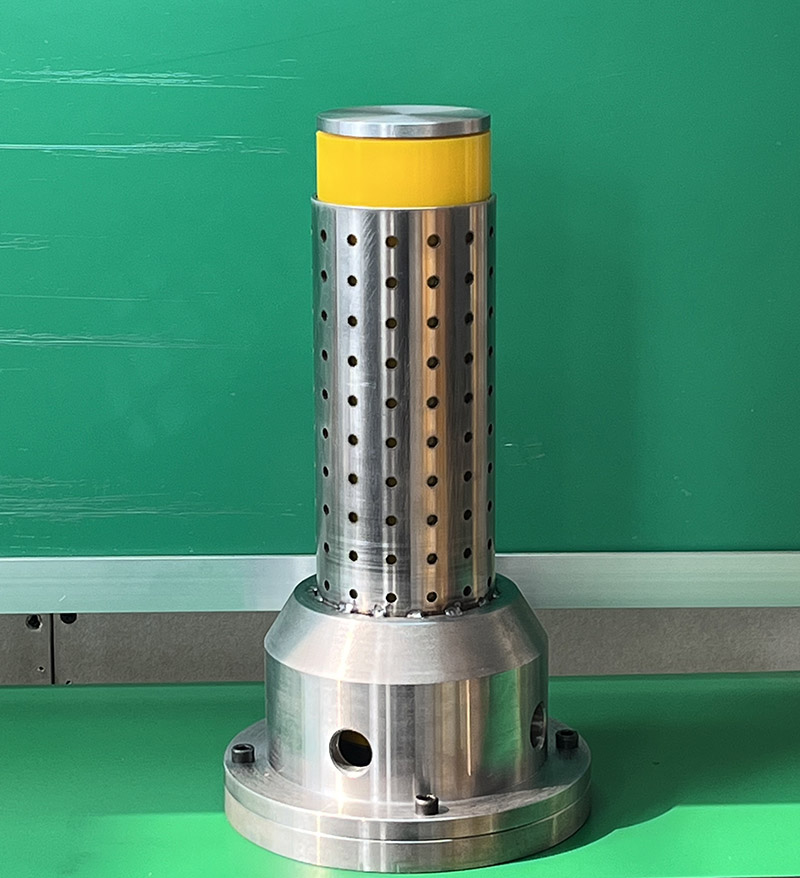

The working principle of cold isostatic pressing is that powder is compacted by applying uniform pressure in all directions thus achieving maximum uniformity of density and microstructure without the geometrical limitations of uniaxial pressing. In cold isostatic pressing (CIP) the powder is placed in a flexible mould made of rubber or Urethane or PVC that does not change shape, but preserves the shape from the mould. It uses a liquid media, such as water or an oil or glycol-mixed water, to apply uniform pressure around the circumference of mould. Typically Pressures of 35-690 MPa are used at ambient temperature or slightly elevated temperatures to compact the powder. Cold iso static pressing parameters of pressure and time are pre-determined to give the material full density.

Cold isostatic pressing has the advantage for producing very large or complex shaped parts and also in the cases where the high initial cost of pressing dies cannot be justified. Using CIP, variety of powders can be pressed isostatically on a commercial scale including metals, ceramics, plastics and composites.