The Steps of Isostatic Pressing Powder Molding

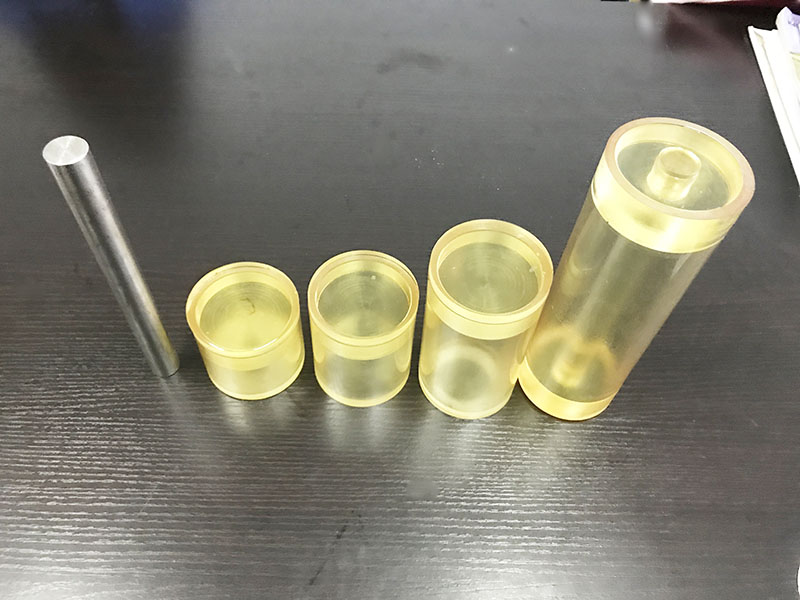

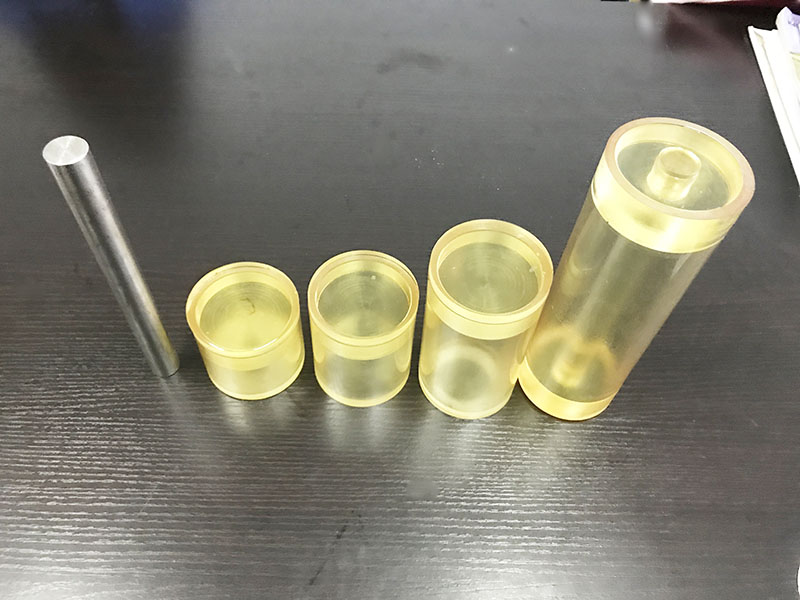

Before isostatic pressing (filling powder)

Isostatic pressing is a powder metallurgy (PM) forming process that applies equal pressure in all directions on a powder compact thus achieving maximum uniformity of density and microstructure without the geometrical limitations of uniaxial pressing.

The isostatic pressing device operates as follows:

The prepared blank is first placed in an elastic mold made of plastic or rubber, placed in a high-pressure container, sealed, and then subjected to a high-pressure liquid medium, and the pressure is transmitted to the elastic mold to add jade to the blank. The pressure is then released to remove the mold and the formed blank is removed from the mold. The liquid medium can be water, oil or glycerin. However, it is advisable to use a medium with low compressibility, such as brake oil or anhydrous glycerin. Elastomeric mold materials should be made of rubber with good elasticity and oil resistance or similar plastics.