The Classification of Cold Isostatic Pressing

Cold isostatic pressing is a method of processing materials. It is quite similar to another process known as metal mold processing. CIP functions based on a principle proposed by Blaise Pascal. This principle is popularly known as Pascal’s law and it states that pressure applied in an enclosed fluid is transmitted in all directions throughout the fluid without any change in the magnitude of the pressure.

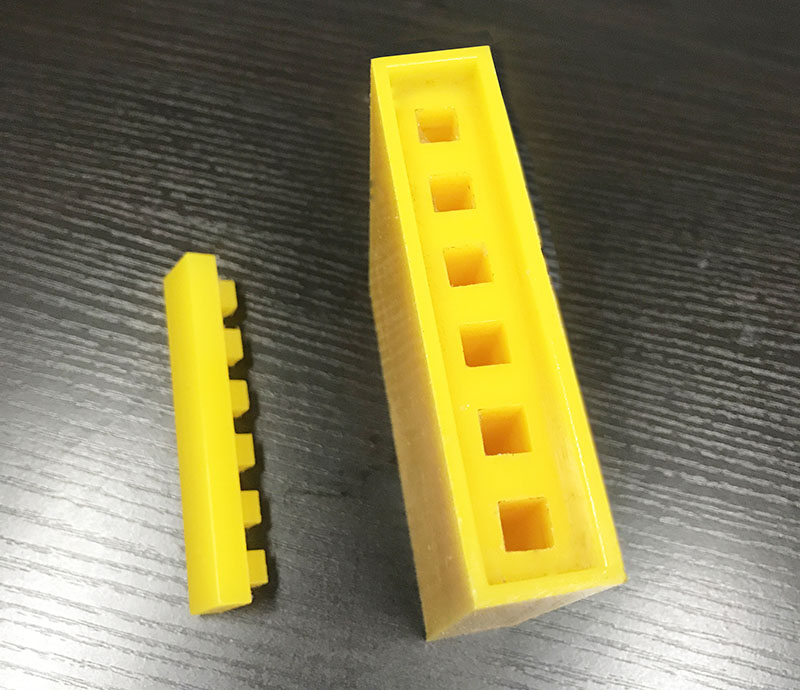

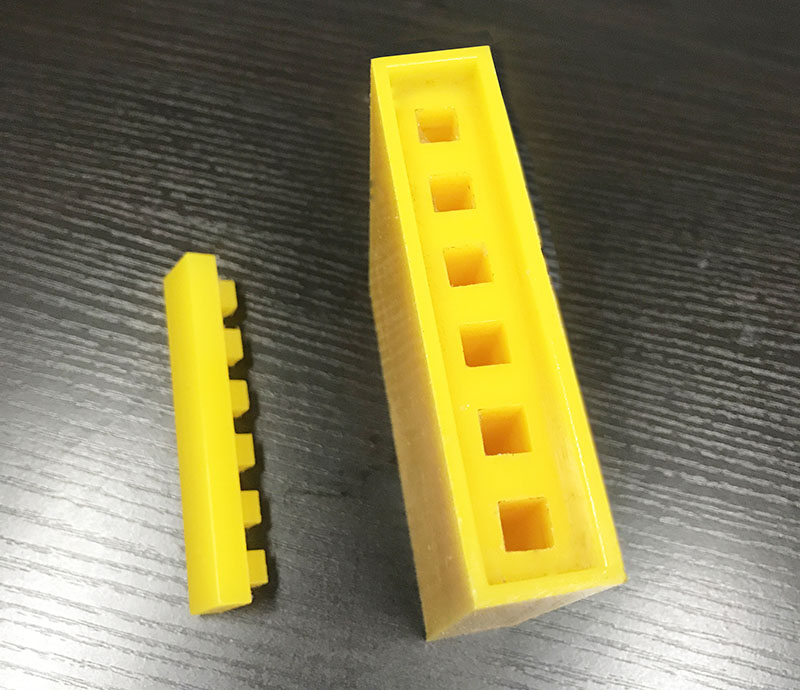

Cold isostatic pressing involves compacting powders by enclosing them in an elastomer mold. An elastomer mold is used because it has low resistance to deformation. Liquid pressure is then applied uniformly to the mold to compress it. At the end of the process, will get a highly compact solid. CIP can be used for plastics, graphite, powdered metallurgy, ceramics, sputtering targets and other materials.

Types of Cold Isostatic Pressing

There are two types of cold isostatic pressing currently recognized all over the world.

Wet Bag Technology

In this process, the powder is filled in a mold and sealed tightly. This occurs outside the pressure vessel. After filling the mold with powder, the mold is submerged in the pressure fluid within the pressure vessel. Then isostatic pressure is applied to the external surface of the mold, compressing the powder into a solid mass.

Dry Bag Technology

In this process, the mold is fixed in the pressure vessel. The powder is filled in the mold while it is still in the pressure vessel. After this, isostatic pressure from the pressure liquid is applied to the external surface of the mold, compressing the powder into a solid mass with a compact microstructure.

Dry bag technology is ideal for the mass production of materials. This process usually takes as little as 1 minute. It is way faster than wet bag technology.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com