Advantages and Applications of Cold Isostatic Pressing

Advantages of Cold Isostatic Pressing

Green Strength

Green strength is a term used to describe the ability of a molded material to withstand manipulation before it is completely hardened. Materials produced via cold isostatic pressing have high green strength. This means that such materials have a higher turnover as they can be sintered or machined faster than other materials.

Uniform Density

Cold isostatic pressing ensures that materials have a uniform density. This means that there will be uniform shrinkage when the material is going through other processes such as sintering. The uniform density can be attributed to the fact that the pressure used in CIP reaches every part of the material with equal magnitude.

Uniform Strength

Since the pressure used to compact the materials is equal in all directions, the material has uniform strength. Materials with uniform strength are usually more efficient than those without uniform strength.

Versatility

CIP can be used to produce difficult shapes which can not be produced by other methods. In addition, it can be used to produce large-sized materials. The only limitation to the size of materials produced by this method is the size of the pressure vessel.

Corrosion Resistance

Cold isostatic pressing improves the corrosion resistance of a material. Thus materials that undergo this process have a longer lifespan than most other materials.

Mechanical Properties

The mechanical properties of cold isostatic pressed materials are improved. Some of the properties improved include ductility and strength.

Applications of Cold Isostatic Pressing

Powder Metallurgy

Cold isostatic pressing is used in powder metallurgy. It is used for the compacting step of powder metallurgy that comes just before the sintering step. In powder metallurgy, CIP is often used to produce complex shapes and dimensions.

Refractory Metals

CIP is used to produce refractory metals. They include tungsten, molybdenum, and tantalum. Tungsten, for example, is used to manufacture wires for filaments in the lamp industry. Generally, refractory metals have a high melting point and are resistant to wear and tear.

Sputtering Targets

Cold Isostatic Pressing (CIP) can press indium tin oxide (ITO) powder into large ceramic preforms, which are then sintered under certain conditions. This method can theoretically produce ceramic targets with a density of 95%.

Automobiles

Cold isostatic pressing is used in manufacturing automobile components. Some of these components include bearings and oil pump gears.

Sintering

Cold isostatic pressing usually comes right before sintering. Cold isostatic pressed products usually have a high green strength that allows them to be sintered faster than other materials.

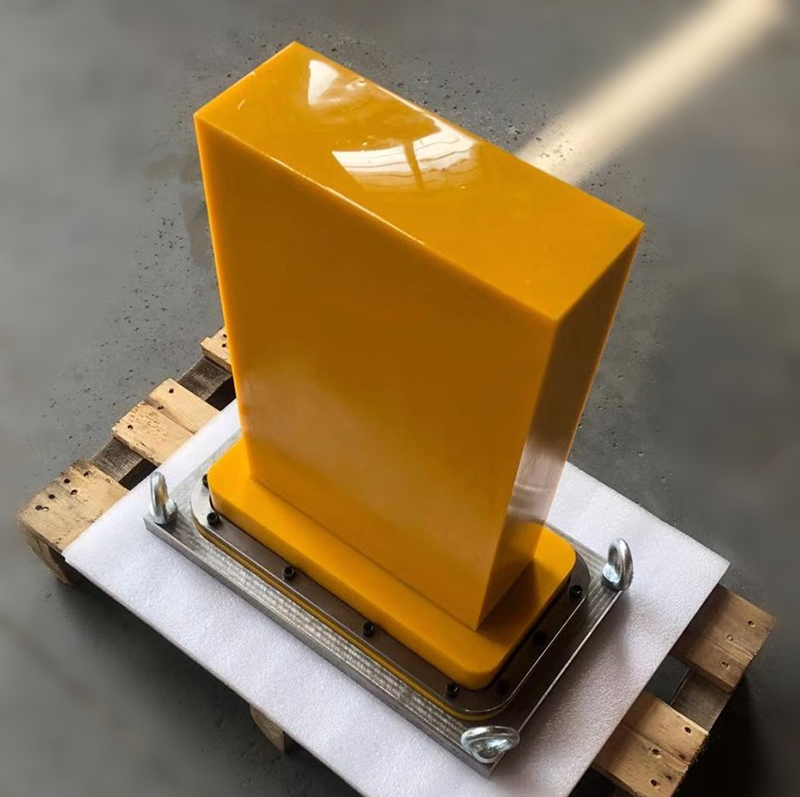

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com