COLD ISOSTATIC PRESSING DESCRIPTION

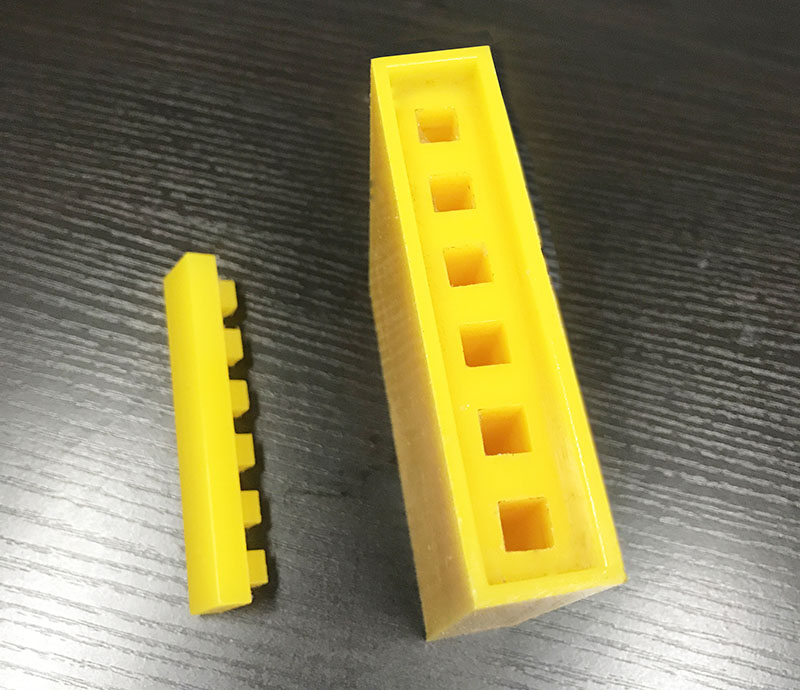

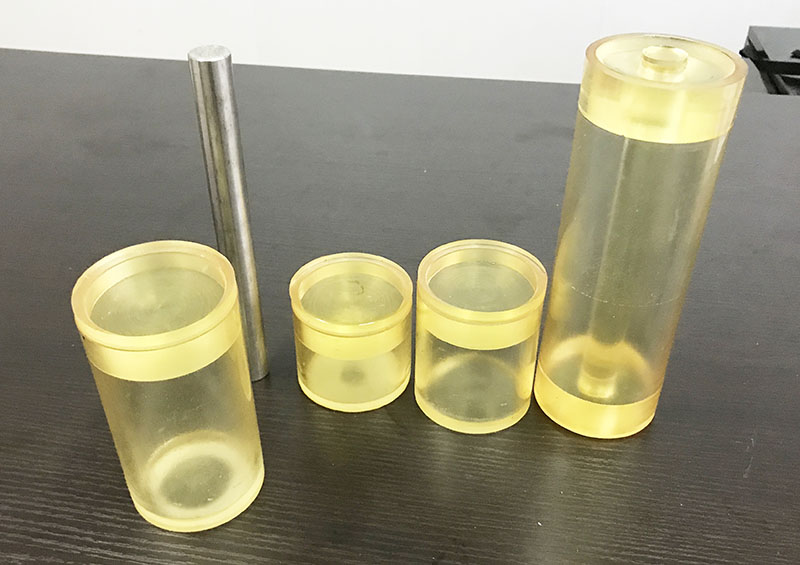

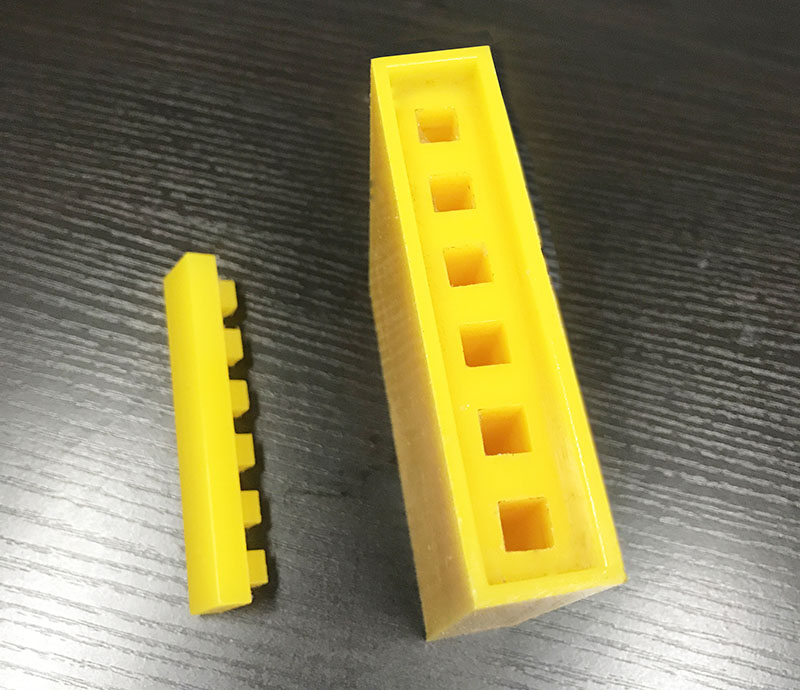

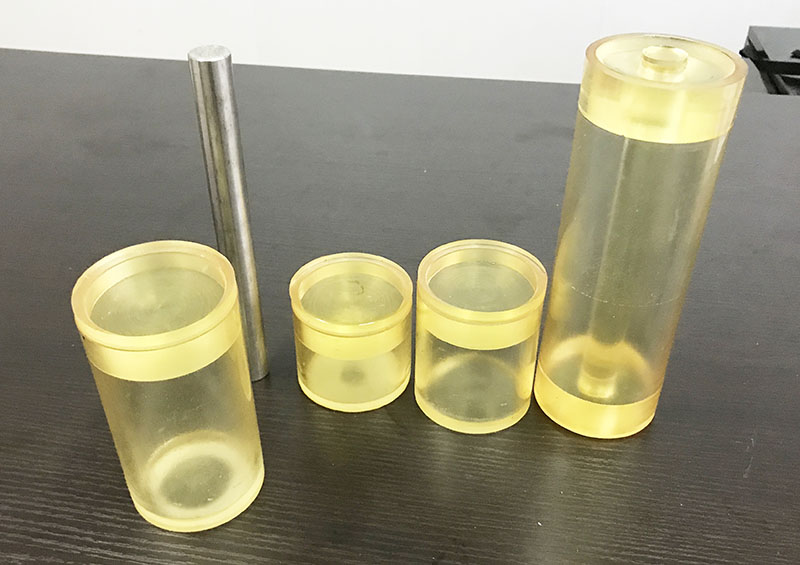

Isostatic Pressing allows for pressing of long and irregularly shapes. The sample is placed within a "wetbag", typically a rubber or latex bag or mold (or even a simple latex glove) and pressure is exerted through a hydraulic fluid such as oil or water.

In isostatic pressing the sample is compressed from all sides equally. Because of this, the pressed sample is usually more stable after pressing and can reach higher density than uniaxial pressing.

Usually the sample is pre-molded e.g. into a disc form in a pellet press die, or a powder is put into a mold which gives it its shapes.

ADVANTAGED OF COLD ISOSTATIC PRESSING:

· Pressing from all sides

· Denser compacts and pellets

· Can press irregular shapes

· Can press long aspect ratio cylinders

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com