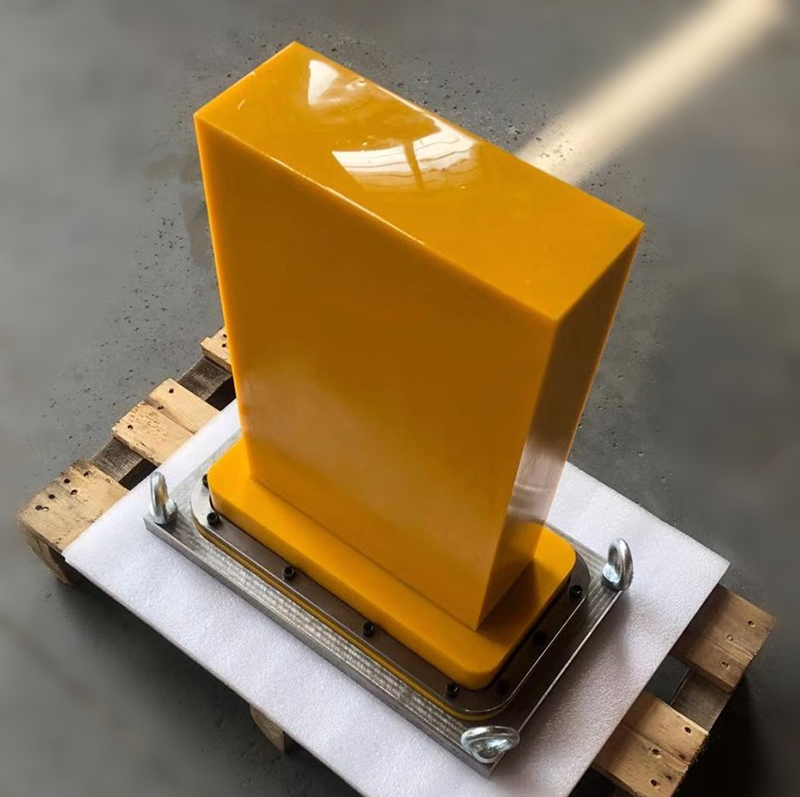

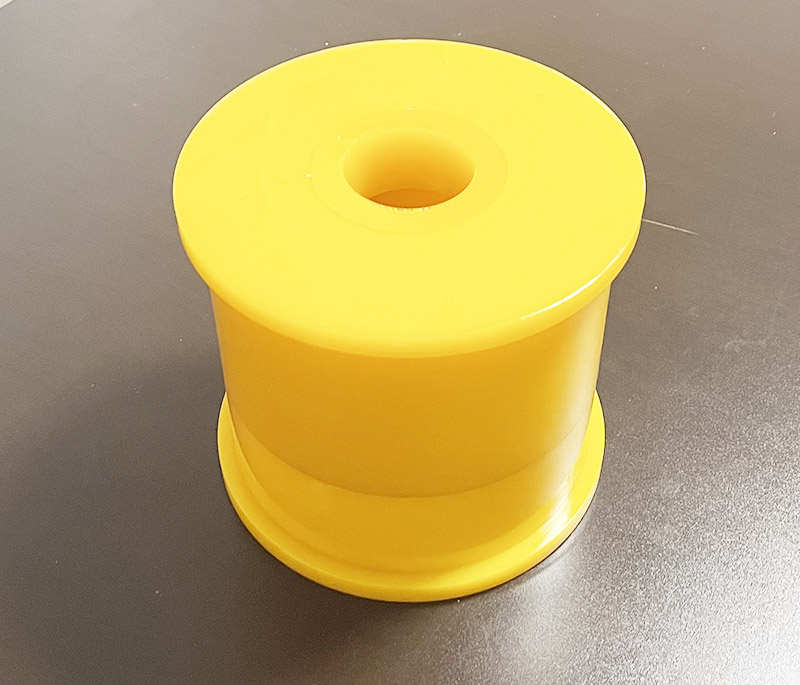

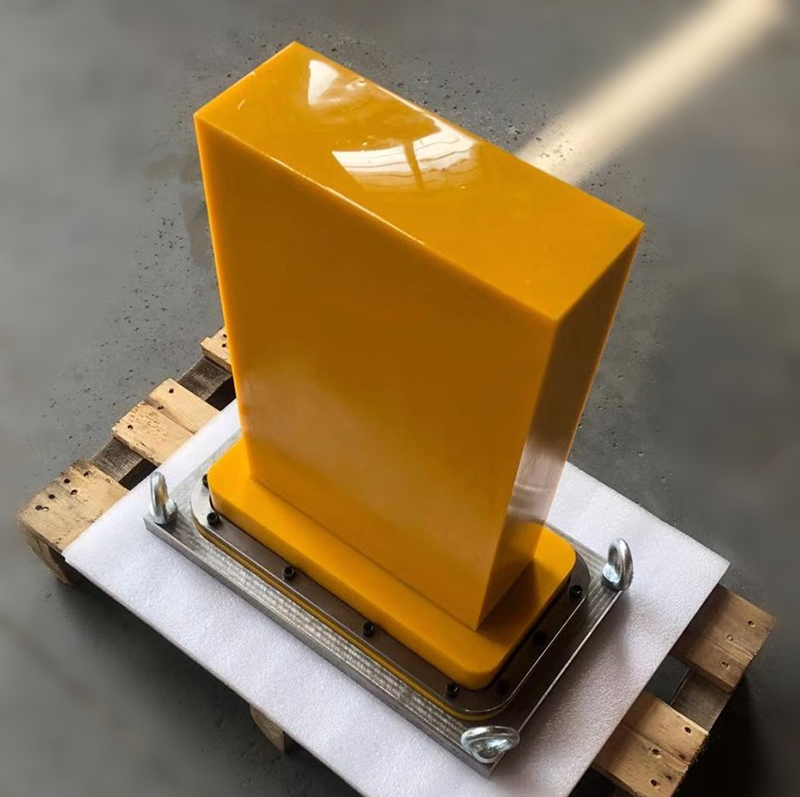

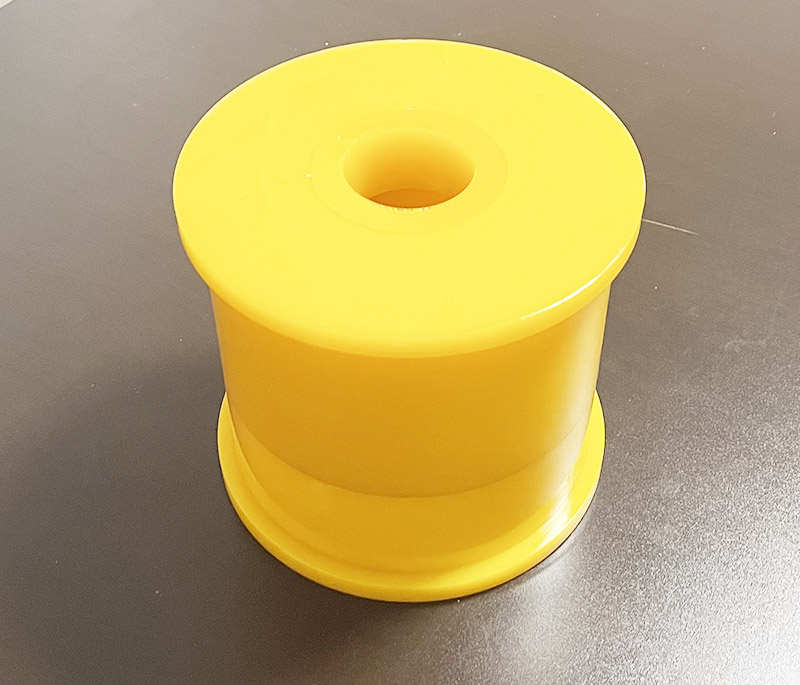

Isostatic presses

Isostatic pressing is one of the primary forming production processes and involves using hydraulic pressure in a tool chamber to press powdery and granular materials into the desired shape. Isostatic pressing allows a solid body with a geometrically defined shape to be created from the shapeless material, which then paves the way to produce difficult-to-shape and complex component geometries with high quality and in bulk.

Cold Isostatic Press

Cold Isostatic Pressing (CIP) is a method of compacting powders into green bodies and near-net shaped in a pressure vessel. The powder, which can be metallic, ceramic or graphite, is sealed in a flexible mold shaped like the end product. High pressure is used up to 600 MPa (6,000 bar/87,000 psi) having water as pressure medium. A high and uniform density is achieved, resulting in easier handling, easier machining and even predictable shrinking during sintering.

CIP applications include compaction of powders into refractory nozzles, metal filters, graphite parts, ceramics, cemented carbides, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com