Isostatic Molding

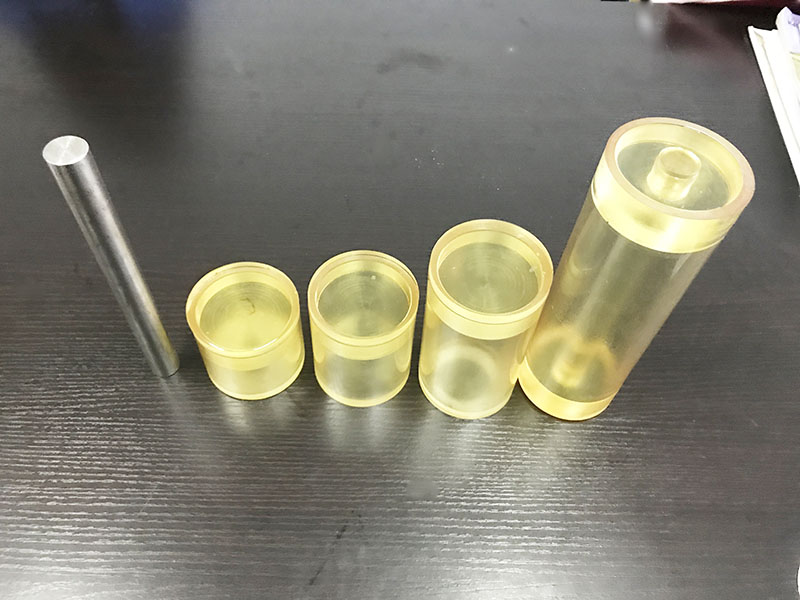

Categories: Cold isostatic pressing mold

Application: Isostatic Molding

InquiryMain description:

Isostatic Molding

Isostatic Molding

Isostatic Molding

Isostatic molding was invented years ago for the processing of ceramic and metal powder.

Subsequently, it was also applied to the granular powder of PTFE, which is inserted in a closed flexible mold to which hydrostatic pressure is then applied through the use of a fluid generally inserted in a metal container.

The uniform and constant application of pressure throughout the cycle time and its uniformity, along the entire shape of the mold, lead to a semifinished with exceptional and uniform physical properties.

Isostatic molded tubes are therefore a semi-finished product preferred to high-end machine sealing components such as lip seals, gaskets, scrapers and other parts for the hydraulic and pneumatic industry.

Compared to standard compression molding, this technology offers some distinctive advantages:

Semi-finished products with the best mechanical properties

More compact chemical structure

Low porosity

Lower internal stress

Thin wall thickness

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com