Isostatic Pressing

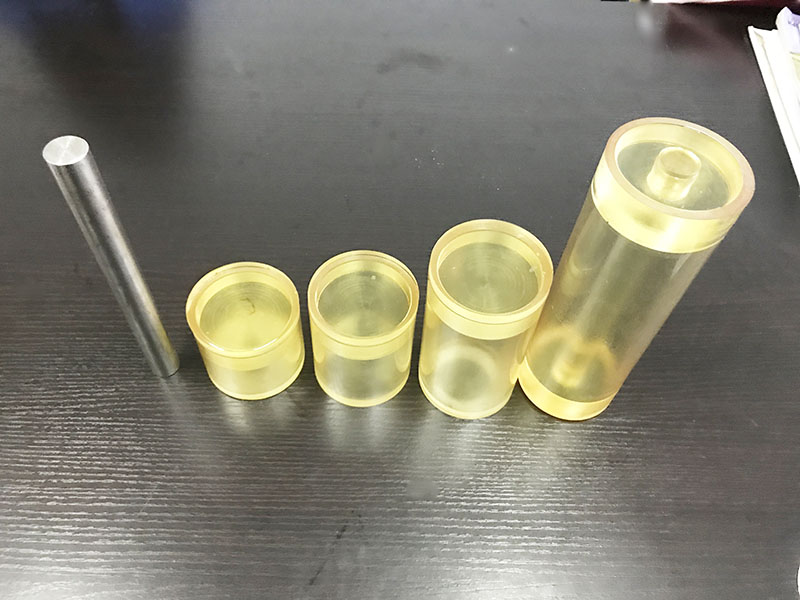

Categories: CIP bags, CIP mold

Application: Isostatic Pressing

InquiryMain description:

Isostatic Pressing

Isostatic Pressing

Isostatic Pressing

What is cold isostatic pressing?

CIP, Cold Isostatic Pressing, is one of material processing methods. It makes use of the principle “A change in the pressure of an enclosed incompressible fluid is conveyed undiminished to every part of the fluid and to the surface of its container.” proposed by the French scientist Blaise Pascal.

What is isostatic pressing in powder metallurgy?

Isostatic pressing is a powder metallurgy (PM) forming process that applies equal pressure in all directions on a powder compact thus achieving maximum uniformity of density and microstructure without the geometrical limitations of uniaxial pressing.

How is powder compacted in isostatic?

The powder is filled in a shaped and flexible mold, sealed, and immersed in liquid in a high-pressure vessel. The liquid is pressurized and the pressure is transmitted through the flexible wall of the mold to the powder, which results in compaction.

What is the pressure used in cold isostatic pressing CIP?

20 to 400 MPa

Isostatic pressing (cold isostatic pressing) consists in compacting a powder in an elastomeric container submersed in a fluid at a pressure of 20 to 400 MPa.

What is Powder Metallurgy in manufacturing process?

Powder metallurgy is a metal-forming process performed by heating compacted metal powders to just below their melting points.

What is the advantage of isostatic pressing?

Advantages of Hot Isostatic Pressing Casting Predictability: Consistency of mechanical properties improved. Mechanical properties: Increased tensile strength, impact strength, and ductility. Improved surface finish: Removes internal porosity enabling smooth, pore free wear surfaces.

What is isostatic presses used for?

Primary applications are the elimination of microshrinkage in castings, the consolidation of powders and diffusion bonding, often referred to as cladding. Hot isostatic pressing is also used as part of a sintering (powder metallurgy) process, for pressure-assisted brazing and for fabrication of metal matrix composites.