Isostatic Graphite

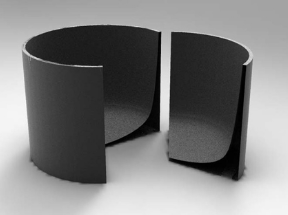

Isostatic graphite is pressed from high-purity graphite. Isostatically pressed graphite refers to graphite materials produced by isostatic pressing, also known as "isotropic" graphite.

Isostatic pressing is to place the material to be pressed in a high-pressure container after sealing, and use the incompressible nature of the liquid medium and the property of uniform pressure transfer to uniformly press the material from all directions. According to the principle of fluid mechanics, its pressure is constant and evenly transmitted to all directions, so the pressure of the powder in the high-pressure container in all directions is uniform and consistent in size. Using this method to densify the powder into a green body is called isostatic pressing.

According to the temperature during isostatic pressing, it can also be divided into cold isostatic pressing, warm isostatic pressing and hot isostatic pressing. The graphite produced by hot isostatic pressing has the highest performance, but it is expensive. For example, the graphite material on the Shenzhou No. 6 escape device is produced by hot isostatic pressing technology, and the value is as high as 20,000/kg.

Isostatic graphite has the following advantages:

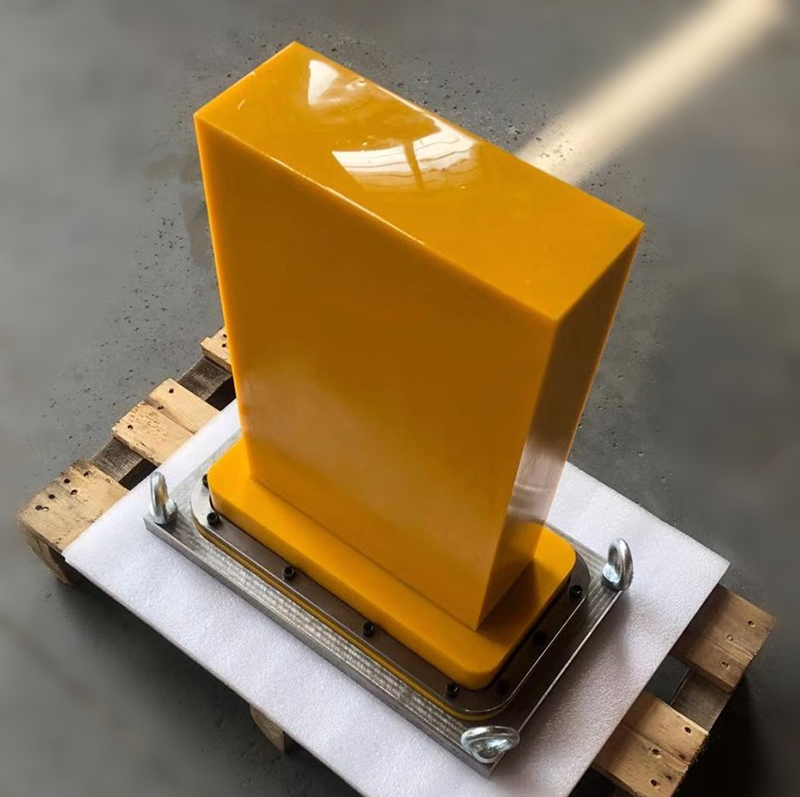

It is suitable for large-scale molding and pressing of special-shaped products. Due to the use of liquid pressure, it means that it is compressed evenly; the pressure can reach 160-200Mpa or even higher, and the compressive strength is high, so it is suitable for pressing large-sized products. The shape of the mold can be changed and directly pressed into a special-shaped blank.

The material has a dense and uniform structure, high hardness and high strength. The liquid is pressurized, and the product is uniformly stressed; the pressure holding time and the pressure relief speed can be selected, and the elastic after-effect of the product after releasing the pressure is small, which is one of the prerequisites for pressing the ultra-fine structure product; the pressure is large and the strength is high, so the hardness of the product and strength are high.

Isotropic (properties independent of size, shape, sampling direction). Due to the pressure in the liquid, the pressure is the same in all directions, and the product is isotropic. Good thermal shock resistance and high temperature resistance. The material is not easy to crack under the conditions of rapid cooling and rapid heating, and has strong oxidation resistance.

Isostatically pressed graphite has the characteristics of high strength, high density, high purity, high chemical stability, dense and uniform structure, high temperature resistance, radiation resistance, high electrical conductivity, good wear resistance, self-lubricating, easy processing, etc. It is widely used in Metallurgy, chemical industry, aerospace, electronics, machinery, nuclear energy and other industrial fields. In particular, large-scale and high-quality special graphite, as an alternative material, has a broad application space and broad application prospects in the field of high-tech and new technology.

Isostatic graphite is a new product developed in the past 50 years in the world and is closely related to today's high technology. It not only has great achievements in civilian use, but also occupies an important position in the cutting-edge of national defense, and belongs to a new type of material. It is an irreplaceable material for the manufacture of single crystal furnaces, metal continuous casting graphite molds, and graphite electrodes for electrical discharge machining.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com