What is Isostatic Pressing and What Advantages of Isostatic Pressing

What is Isostatic Pressing

lsostatic pressing is a powder metallurgy(PM)forming process that applies equal pressure in all directions on a powder compact thus achieving maximum uniformity of density and microstructure without the geometrical limitations of uniaxial pressing

lsostatic pressing is performed"cold"or"hot."Cold isostatic pressing(CIP)is used to

compact green parts at ambient temperatures,while hot isostaticpressing(HIP)is used to fully consolidate parts at elevated temperatures by solid-state diffusion.HIP can also be used to eliminate residual porosity from a sintered PM part.

Advantages of lsostatic Press

· Powder is compacted with the same pressure in all directions,and since no lubricant is needed, high and uniform density can be achieved.

· The process removes many of the constraints that limit the geometry of parts compacted unidirectionally in rigid dies.

· It is applicable to difficult-to-compact and expensive materials such as superalloys titanium, tool steels, stainless steel, and beryllium, with material utilization thatis highly efficient.

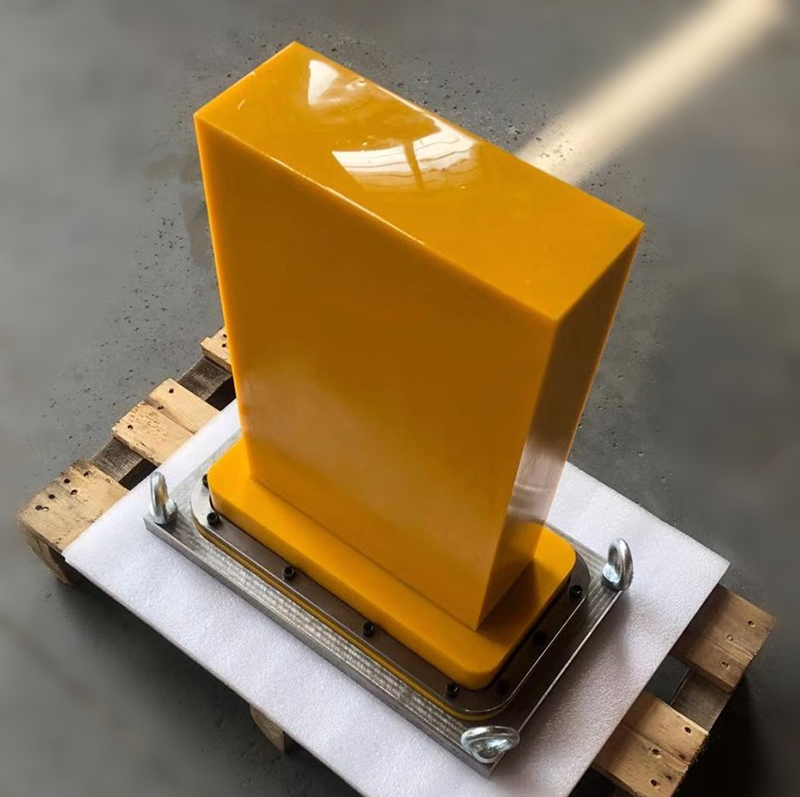

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com