Ceramics Isostatic Pressing

Ceramic isostatic pressing, also known as hydrostatic forming, is a molding method that utilizes the incompressibility of the liquid medium and the uniform transfer of pressure.

The pressure applied to the sample in the high-pressure vessel is like the pressure of the hydrostatic water at the same depth, so it is called hydrostatic pressure or isostatic pressure. The molding process according to this principle is called hydrostatic molding, or It is called isostatic pressing.

The isostatic pressing method has the following characteristics:

(1) It is possible to mold a product having a complicated shape, a large size, and a thin and long length which cannot be produced by a general method, and has a high molding quality.

(2) It is convenient to increase the molding pressure without increasing the difficulty of operation, and the pressure effect is better than other dry pressing methods.

(3) Since the blanks are uniformly pressed in various directions, the density is large and uniform, and the firing shrinkage is small, so that it is not easily deformed.

(4) The mold is easy to manufacture, has a long life and low cost.

(5) It is possible to use less or no binder.

Advantages and disadvantages of isostatic pressing:

high density, good quality, can be molded in large quantities

Disadvantages:

high cost, unable to make special shapes

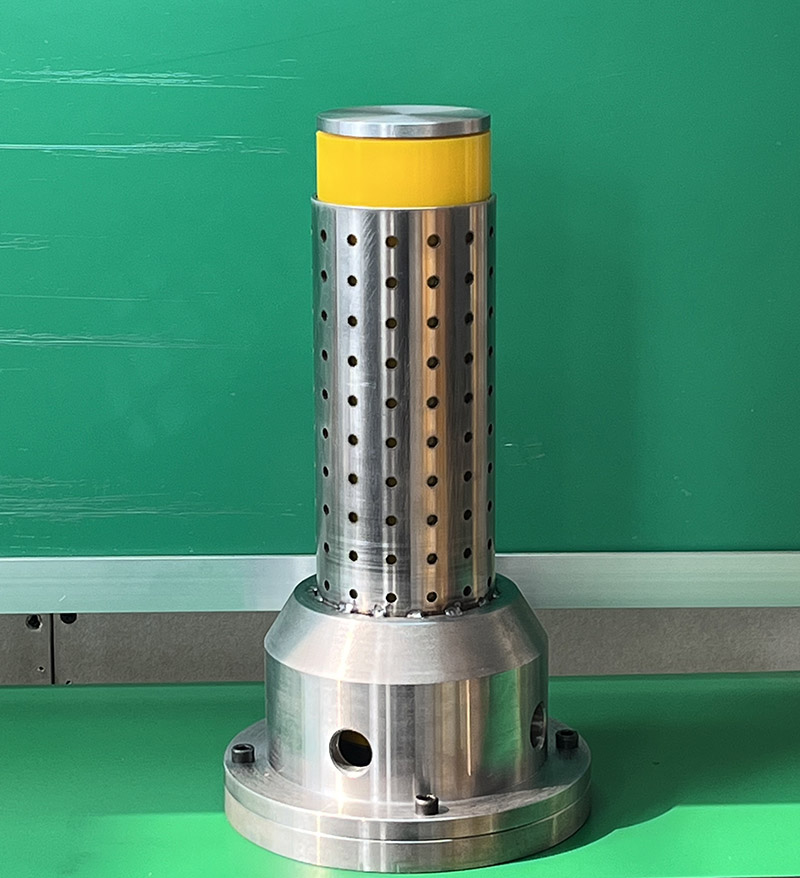

Before isostatic pressing (filling powder)

The isostatic pressing device operates as follows:

The prepared blank is first placed in an elastic mold made of plastic or rubber, placed in a high-pressure container, sealed, and then subjected to a high-pressure liquid medium, and the pressure is transmitted to the elastic mold to add jade to the blank. The pressure is then released to remove the mold and the formed blank is removed from the mold. The liquid medium can be water, oil or glycerin. However, it is advisable to use a medium with low compressibility, such as brake oil or anhydrous glycerin. Elastomeric mold materials should be made of rubber with good elasticity and oil resistance or similar plastics.

Isostatic molding method

The isostatic pressing method has two types: cold isostatic pressing and hot isostatic pressing.

Cold isostatic pressing is further divided into wet isostatic pressing and dry isostatic pressing. The mold is in a high-pressure liquid and the parties are pressed, so it is called wet isostatic pressing. It is mainly suitable for molding multi-variety, complex shape, small output and large-scale products.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com