Isostatic Pressing

Categories: Cold isostatic pressing mold

Application: Isostatic Pressing

InquiryMain description:

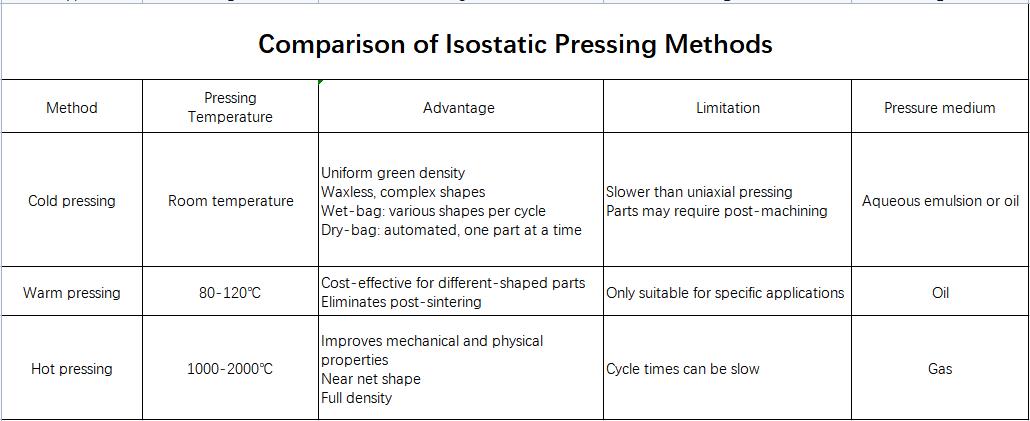

Isostatic pressing applies a uniform, equal force over the entire product, regardless of shape or size. It thus offers unique benefits for ceramic and refractory applications. The ability to form product shapes to precise tolerances (reducing costly machining) has been a major driving force for its commercial development.