ISO Molds for Powder Metallurgy

Categories: Industry news

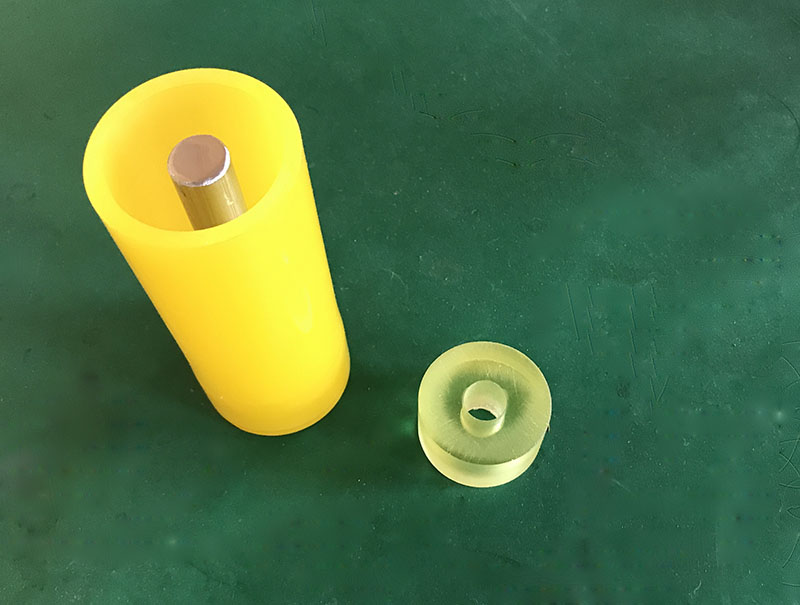

Application: ISO Molds for Powder Metallurgy

InquiryMain description:

ISO Molds for Powder Metallurgy

ISO Molds for Powder Metallurgy

ISO Molds for Powder Metallurgy

In general injection molding, very fine powder is used, and a large amount of thermoplastic binder is injected into the molding die. Compression molding is basically filled with dry powder into the mold by gravity, and it is extruded by external pressure. In the actual application process, compression molding is widely used. For example, our cold closed steel mold pressing, cold isostatic pressing, hot isostatic pressing, and warm pressing are all compression molding.

The powder metallurgy forming process, stamping forming and injection molding parts, make the size and shape of the complexity degree is limited. Powder metallurgy products have high hardness and wear resistance, but because the fatigue resistance of the shaft cannot be guaranteed, a small defect may lead to destruction. Powder metallurgy is not suitable for larger gears, more powerful gears can be launched.

Powder metallurgy technology can reduce the segregation of alloy components and eliminate coarse and uneven casting structures. In the preparation of high-performance rare earth permanent magnet materials, rare earth hydrogen storage materials, rare earth luminescent materials, rare earth catalysts, high temperature superconducting materials, new metal materials (such as Al-Li alloys, heat-resistant Al alloys, super alloys, powder corrosion-resistant stainless steel, powder High-speed steel, high-temperature structural materials of intermetallic compounds, etc.) play an important role. Various types of composites can be easily realized, and the characteristics of each component material can be fully utilized. It is a low-cost production technology for high-performance metal matrix and ceramic composite materials.

A series of high-performance non-equilibrium materials such as amorphous, microcrystalline, quasicrystalline, nanocrystalline and supersaturated solid solutions can be prepared, and these materials have excellent electrical, magnetic, optical and mechanical properties.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com