The Elasticity of Isostatic Pressing Mold - Polyurethane Isostatic Pressing Mold

Isostatic Pressing Technology

The forming mechanism of the carbon paste or pressed powder in the mold is directly compressed in the high pressure container to form the green, the operating procedures and technological rules of the liquid isostatic pressing forming. Isostatic molding is often used to produce fine particle structure, homogeneous high-density graphite or isotropic graphite. Isostatic molding is divided into two types, namely liquid isostatic molding with liquid as the pressure transfer medium and gas isostatic molding with gas as the pressure transfer medium. Gas isostatic molding is generally carried out under the state of heating (mainly used in powder metallurgy industry), and liquid isostatic molding is mainly used to produce carbon products.

The basic principle of liquid isostatic pressing is to follow the PASCAL's law of fluid mechanics, that is, in a closed container filled with liquid, the pressure applied to any point in the fluid, must be transferred to any part of the container with the same value. The isostatic pressing process is to load the powder material required to be pressed into the elastic mold, and tie the mold mouth tightly, the mold with material is placed in the high-pressure container, and then the high-pressure container entrance is tightly sealed. Pressurized media generally for transformer oil, to high pressure vessel with ultra-high pressure pump injection transformer oil on mold uniform pressure, the pressure in the container could rise to 100 ~ 600 mpa, keep after a certain period of time, gradually reduce the pressure, discharge medium, open container entry, mold, discharged from the mold in the molding of green, Further heat treatment (roasting, graphitization) and mechanical processing to obtain the required product.

Liquid isostatic pressing has the following characteristics: (1) The density distribution of the pressed green billet is more uniform, and the internal structure defects are less, which is incomparable to other forming processes. (2) It is possible to produce green billets with volume density controlled by adjusting the pressure in the liquid isostatic pressure high-pressure vessel. The pressure of the liquid isostatic pressure is proportional to the density of the green billet. (3) Because the pressure in the high pressure vessel is much higher than that in the general extrusion or molding, it can be used for the non-bonding agent molding of petroleum coke powder. (4) can produce more complex shape products, such as directly pressed ball or tubular green. The operation of isostatic pressing is more difficult, and the production efficiency is low, so the production cost is high. In addition, the shape of the green blank obtained from isostatic pressing is somewhat irregular, and it must be processed mechanically after roasting or graphitization. Therefore, the mold size designed during molding should be set aside the shrinkage allowance and processing allowance of the green blank during heat treatment.

Equipment liquid isostatic molding equipment is mainly composed of elastic mold, high pressure vessel, frame and hydraulic system. The elastic mold is generally made of rubber or resin synthetic materials. The size and shape of the material particles have a great impact on the life of the elastic mold. The mold design is the key technical problem of isostatic pressing. Most high-pressure vessels are made of high-strength alloy steel directly cast and machined by machine tools. They are thick-walled metal simplified, which can resist strong liquid pressure. There are also many forms of simplified structures, such as double-layer composite simplified, prestressed steel wire winding reinforced cylinder, etc. The hydraulic system is composed of low pressure pump, high pressure pump and supercharger and various valves. It begins with the low pressure pump with large flow rate, and reaches a certain pressure after the high pressure pump supplies oil, and further increases the liquid pressure in the high pressure vessel by the supercharger.

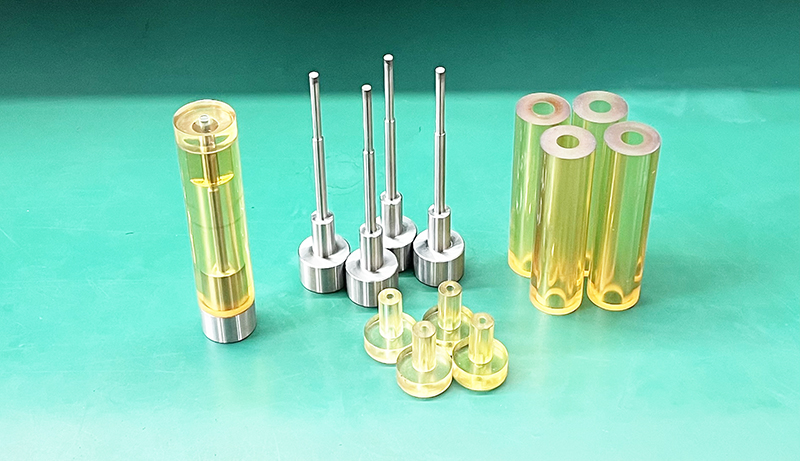

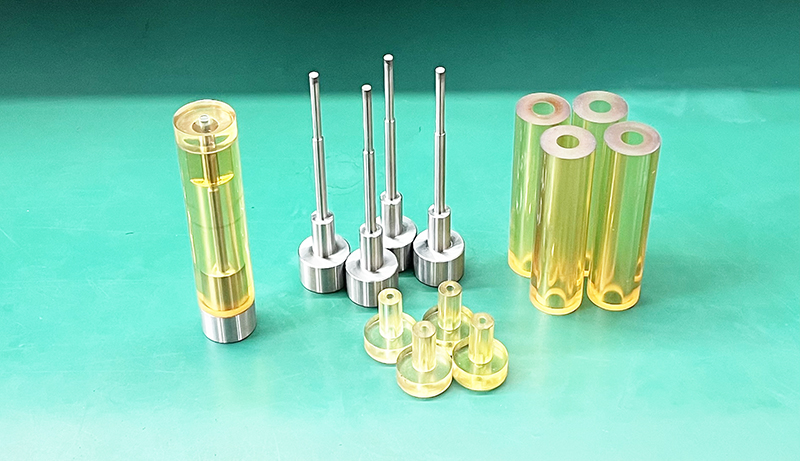

Polyurethane Isostatic Pressing Mold

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold