Isostatic Pressing Process

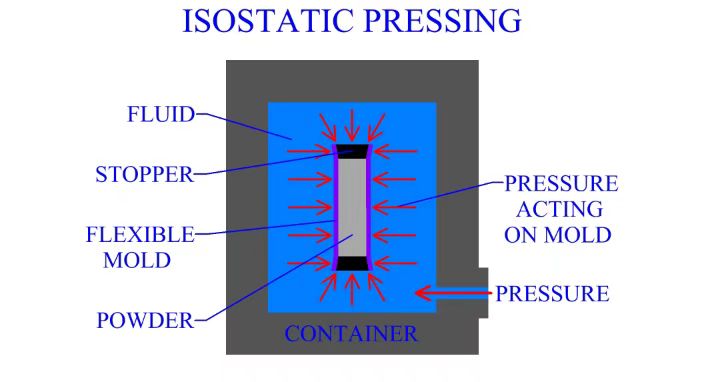

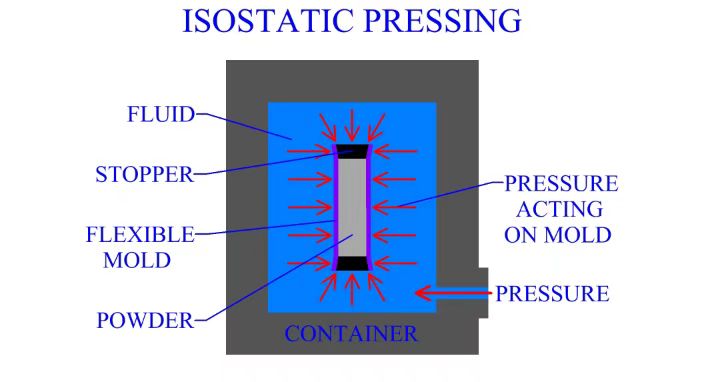

The principle of isostatic pressing is: using the incompressibility and uniform pressure transmission of the liquid medium, put the prepared blank into an elastic mold made of plastic or rubber, put it into a high-pressure container, seal it, and inject the high-pressure liquid medium through a pressure pump. And transfer the pressure to the elastic die to increase the pressure on the blank pressure.

This is a component-forming process where pressure is applied uniformly (using gas or liquid) to a hermetically sealed container filled with compacted metal powder. Isostatic pressing can be performed at elevated temperatures, known as hot isostatic pressing (HIP), or at ambient temperatures, known as cold isostatic pressing (CIP). Hot isostatic pressing can be used to manufacture metal components directly, or to densify parts from other powder metallurgy processes.

Isostatic pressing has several benefits over the commonly used press and sinter method, including equal compaction in all directions and a more uniform final component density. The isostatic pressing machine is used to press the green compact with high density and uniformity, and the density can be easily controlled. Each cylinder of the isostatic press can press multiple products of the same or different shapes and sizes, and the process is simple.

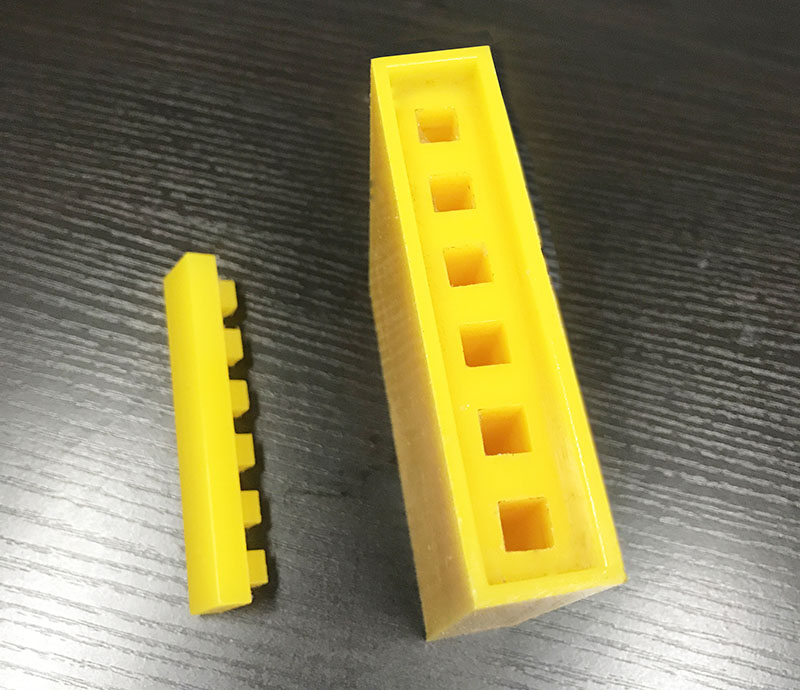

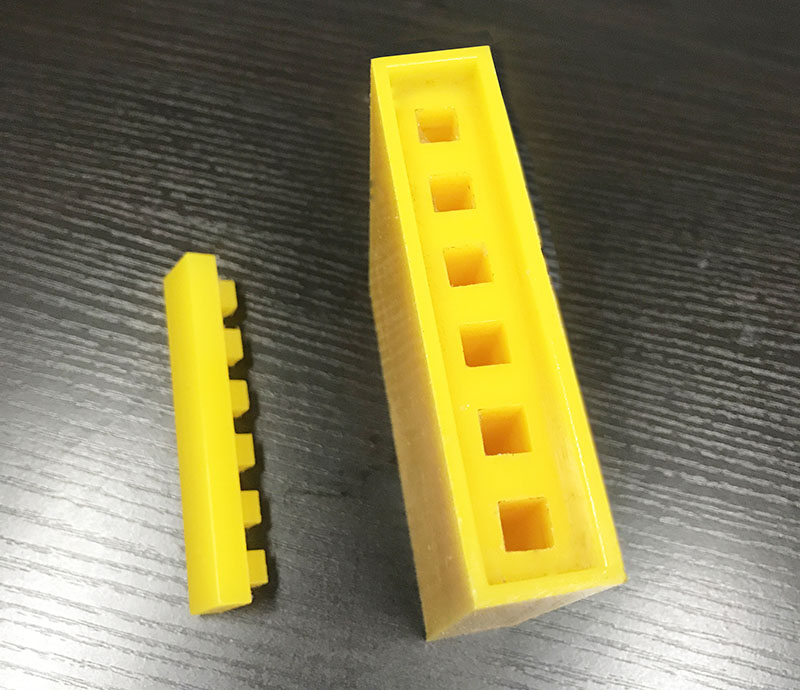

Some Isostatic Pressing bags/mold/tooling, CIP bags/mold/tooling, ISO bags/mold/tooling

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com