The Advantages and Applications of PTFE

Categories: Industry news

Application: The Advantages and Applications of PTFE

InquiryMain description:

The Advantages and Applications of PTFE

The Advantages and Applications of PTFE

The Advantages and Applications of PTFE

Polytetrafluoroethylene (PTFE) advantages:

The advantages of polytetrafluoroethylene (PTFE) are as follows:

1. High temperature resistance - working temperature up to 250 ℃.

2. Low temperature resistance - good mechanical toughness; 5% elongation can be maintained even when the temperature drops to -196°C.

3. Corrosion resistance - inert to most chemicals and solvents, strong acid and alkali resistance, water and various organic solvents.

4. Weather Resistant - Has the best aging life of any plastic.

5. High Lubrication - The lowest coefficient of friction among solid materials.

6. Non-stick - is the smallest surface tension in a solid material that does not stick to anything.

7. Non-toxic - It is physiologically inert, and it has no adverse reactions when it is implanted in the body as an artificial blood vessel and an organ for a long time.

Main applications of polytetrafluoroethylene (PTFE):

PTFE has a high melting point and a high melt viscosity, and is sensitive to shearing in an amorphous state, which is prone to melt fracture. Therefore, conventional thermoplastic molding processes such as melt extrusion and injection molding cannot be used, and only similar powders can be used. Metallurgical method for sintering.

The manufacture of filled PTFE is the same as the molding of PTFE. It can be processed by pre-forming, free sintering, or by plunger extrusion. The above processing technology is generally suitable for products with a certain wall thickness, not suitable for the processing of PTFE films. In recent years, a lot of research has been carried out in China. The more mature processing technologies are: calendering for disperse PTFE resin; metal turning processing using the characteristics of low hardness and good toughness of PTFE sintered products; in addition, there is a conventional extrusion method and In the extrusion processing of the calendering method, the resin is directly processed with raw materials without being melted and plasticized.

In addition to the primary processing technology introduced above, PTFE processing also has some newly developed secondary processing technologies worthy of attention, such as PTFE vacuum forming technology, hot press forming and hot blow molding technology, isobaric forming processing technology, etc. PTFE is the preferred material for corrosion-resistant lining of corrosion-resistant pipes, fittings, bellows, pump bodies, valves, kettles, tanks, towers and various standard equipment; as a sealing material, it is widely used in machinery, petrochemical, transportation, textile and construction industries. Wide range; PTFE can also be used as valves, bearings, piston rings, guide rails and other parts that require corrosion resistance and low friction; according to PTFE film treatment, it has selectable air permeability, and can be used as separation material, selectively permeating gas or liquid, especially filtering Corrosive liquid; due to the excellent biocompatibility of PTFE, many people have carried out in-depth research on it as a biological material in recent years. In recent years, PTFE membrane has been developed at home and abroad as artificial organs, such as artificial blood vessels, Heart valves, etc., for example, have been clinically used as artificial blood vessels and prosthesis stent materials in rhinoplasty, and have achieved good results.

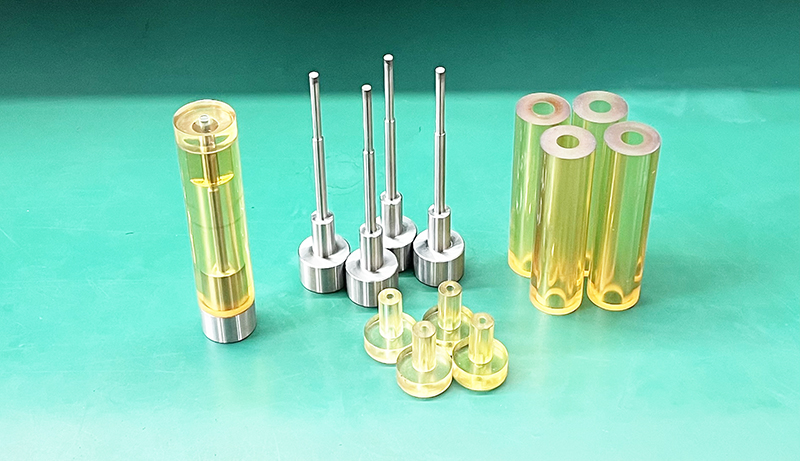

Some CIP bags we made which are suitable PTFE