Isostatic Pressing Process

According to Pascal's principle, it is used for the molding of various powder products under ultra-high pressure. The working principle of isostatic pressing is Pascal's law: "The pressure of the medium (liquid or gas) in a closed container can be transmitted equally in all directions.

The working principle is that the powder is installed in the elastic mold and put into the ultra-high pressure working cylinder, and the hydraulic medium is injected into the ultra-high pressure working cylinder by the pump, and it acts on all the surfaces of the mold evenly, so that the powder is uniformly compressed and formed.

The principle of isostatic pressing technology is based on Pascal's principle, using the technology of forming products in the state of equal ultra-high pressure in all directions. The finished product has good isotropy, and has a good effect on parts with high performance requirements, complex shapes and large slenderness ratios. "Isostatic pressing technology has a history of more than 70 years, and it was mainly used in powder metallurgy molding in the initial stage; in the past 20 years, isostatic pressing technology has been widely used in ceramic casting, atomic energy, plastics, graphite, ceramics, permanent magnets, and high-voltage electromagnetic porcelain bottles. , biological drug preparation, food preservation, high-performance materials, military and other fields.

According to the temperature during forming and consolidation, isostatic pressing technology is divided into three different types: cold isostatic pressing, warm isostatic pressing and hot isostatic pressing. Cold Isostatic Pressing (CIP for short) is a process at room temperature, usually with rubber or plastic as the mold material, and liquid as the pressure medium, mainly used for powder material molding, for further sintering, forging or Hot isostatic pressing process is provided. The general operating pressure is 100~630MPa. Warm isostatic pressing technology, the pressing temperature is generally 80 ~ 500 ℃. Use special liquid or gas to transmit pressure, and the operating pressure is about 100MPa. It is mainly used for graphite and polyamide rubber materials that cannot be formed by powder materials at room temperature. in order to obtain solid bodies at elevated temperatures. Hot isostatic pressing technology (HIP for short) (HIP) is a process technology that makes materials undergo isostatic pressing under the simultaneous action of high temperature and high pressure. It is not only used for the consolidation of powders. The eyelash forming and sintering two-step operation are completed together. It is also used for diffusion bonding of workpieces, elimination of casting defects, and production of complex-shaped parts. In hot isostatic pressing, inert gases such as argon and ammonia are generally used as the pressure transmission medium, and metal or glass is usually used as the covering material. The working temperature is generally 1000~2200℃, and the working pressure is usually 100~200MPa.

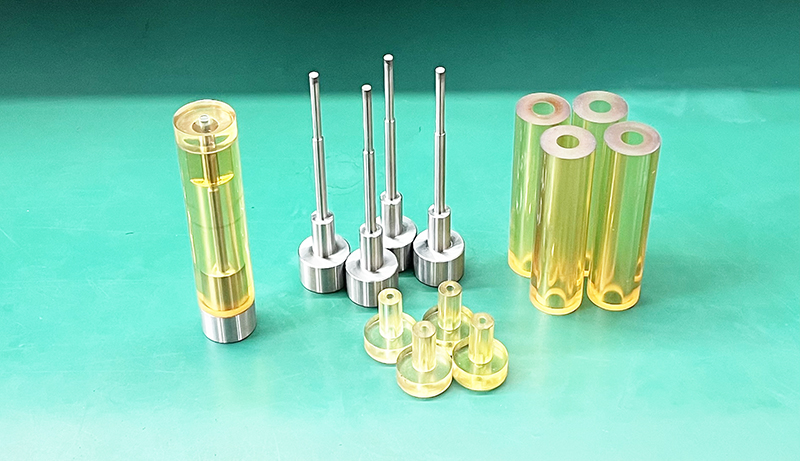

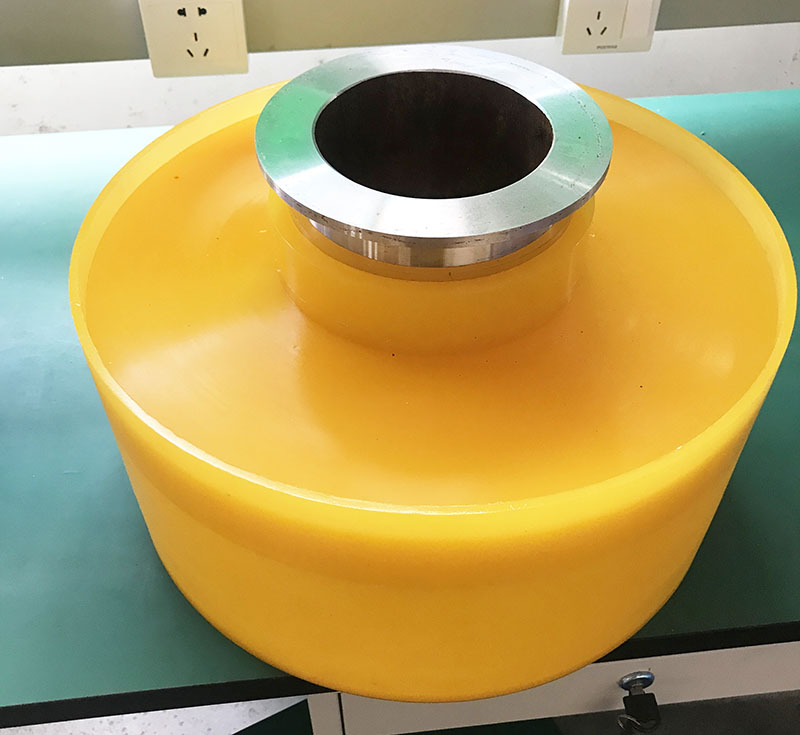

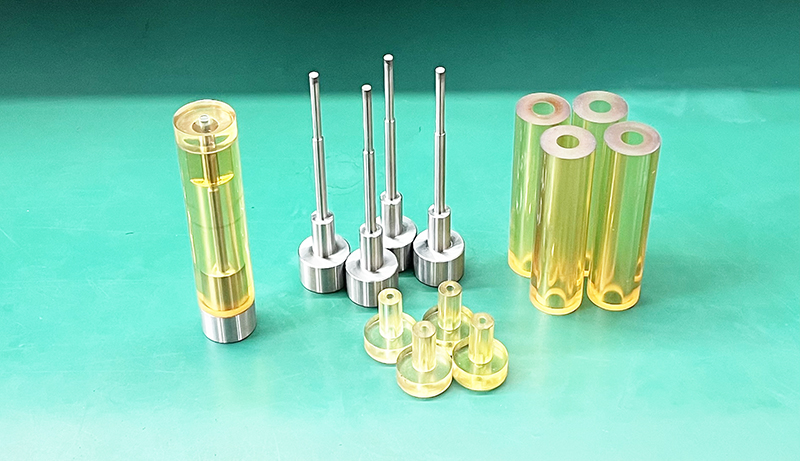

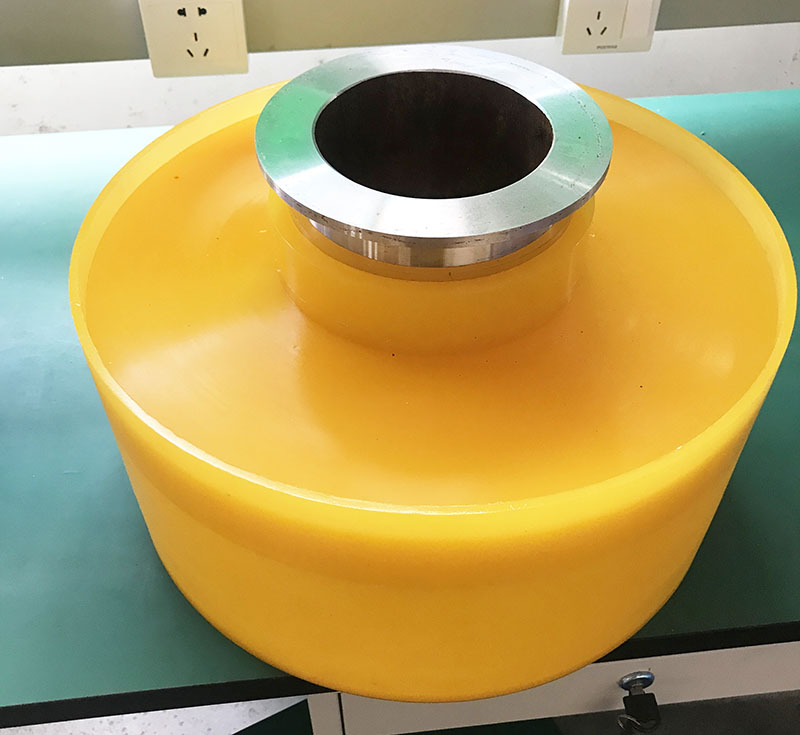

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com