Cold Isostatic Pressing Graphite Crucible Molds

With the rapid development of modern science and technology, as well as the rise of global low-carbon economy, energy saving and high efficiency, in modern enterprise manufacturing, we should not only consider the traditional indicators such as low cost, high efficiency and short cycle, but also consider various indicators such as resources, environment and energy consumption utilization. Therefore, it is extra important to change the mechanical processing technology of products to meet the increasing demand of the industrial chain supply under the condition of similar or unchanged performance and cycle.

Graphite is an important component of refractory materials. Graphite is widely used in industry, and we use more artificial graphite in industry, which is often said to be special graphite. It is mainly made of coke and adhesive asphalt or petroleum coke mixed and molded, baked in the oven at 1000℃ to 1300℃ temperature, impregnated, and then graphitized at 2500℃ to 3000℃ high temperature, the carbon body processed into crystalline graphite structure, and finally through mechanical processing to obtain graphite blocks or preforms. Graphite crucible is one of the essential tools for modern industrial metal smelting because of its graphite super high thermal conductivity and high temperature resistance, even in the smelting of special steel and non-ferrous metals and their alloys is also very important. At present, the graphite crucible used as an accessory in the photovoltaic market is mainly divided into die casting and isostatic pressing according to the different forming methods. Because the isostatic graphite products have good chemical stability, and after mechanical processing of graphite crucible products, with good corrosion resistance, thermal conductivity, oxidation resistance and other characteristics, is widely used in metallurgy, casting, machinery, chemical industry.

2. Characteristics of graphite crucible precast

According to the different forming process, the production process of graphite crucible can be divided into molding process and cold isostatic molding process. The adhesive property of clay is used to complete the plastic forming process, but the process has the unfavorable characteristics of long production cycle, high labor intensity and low working efficiency. Burning coal will cause a lot of pollution, because of less investment, most of them adopt this process; Cold isostatic pressing equipment pressing and forming process is made of clean energy, which fundamentally solves the problem of environmental pollution, and reduces nearly 10 production processes, greatly shortens the production cycle, and the work efficiency has been improved.

Compared with the traditional rolling molding technology, the crucible isostatic molding has the advantages of uniform texture, high density, energy saving and strong oxidation resistance. Isostatic pressure forming crucible is under the condition of isostatic pressure processing molding, so the processing of the crucible parts of the forming pressure is equal, forming the structure of the parts of the crucible more consistent, its internal more dense and lower porosity, the chemical stability and thermal conductivity of the crucible can be significantly improved, the use of crucible performance is greatly improved.

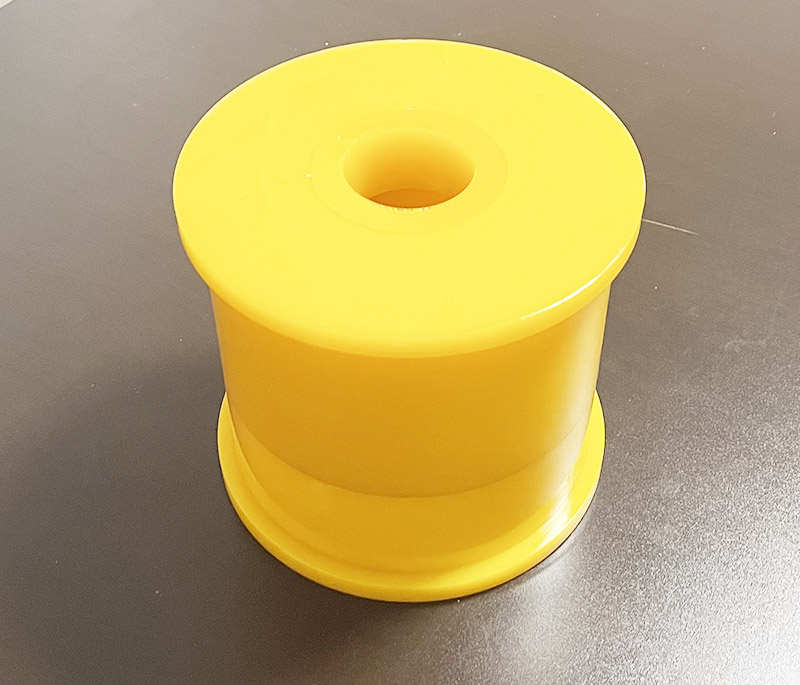

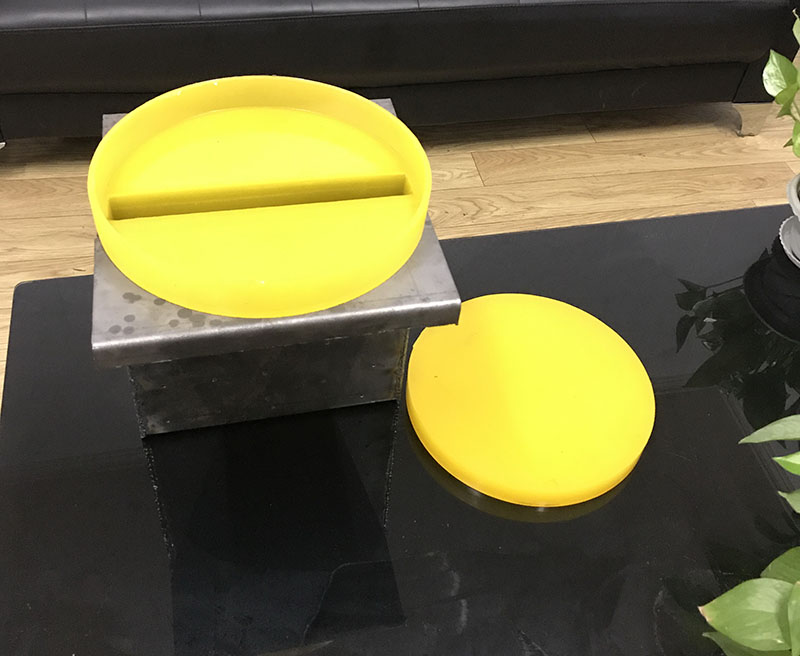

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com