Isostatic Pressing of Ceramics

Isostatic pressing is a special forming method developed on the basis of traditional dry pressing. It uses the fluid to transfer pressure from all directions evenly to the pressure of the powder in the elastic mold because of the consistency of the internal pressure of the fluid, the pressure of the powder in all directions is the same, so it can avoid the difference in the density of the billet body.

Isostatic pressing can be divided into wet bag isostatic pressure and dry bag isostatic pressure

Wet-bag isostatic pressure: It can shape more complex products, but only intermittent operation.

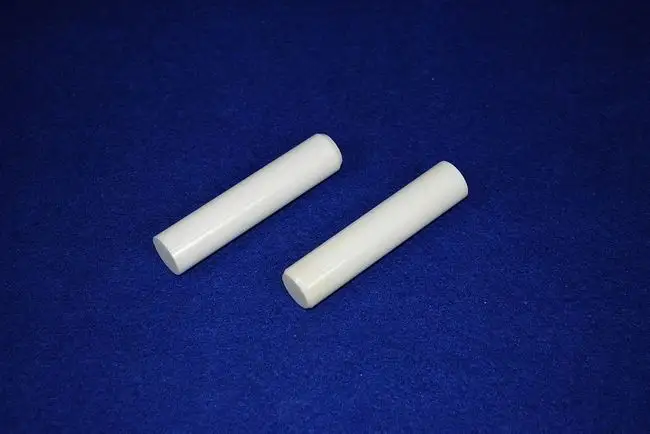

Dry bag isostatic pressing: it can realize automatic continuous operation, but it can only form the products with simple shapes such as square, round, tubular and so on.

Isostatic pressing can obtain uniform and dense blank body, ceramic sintering shrinkage is small and uniform shrinkage in all directions, but the equipment is more complex, expensive, production efficiency is not high, only suitable for the production of special requirements of materials.

Isostatic pressing process and characteristics

Cold Isostatic Pressing (CIP), as it is commonly called, can be divided into two forms according to the different forming process: wet bag and dry bag.

Wet bag isostatic pressing technology is to put granulated ceramic powder or pre-formed billet into the deformable rubber envelope, and then apply uniform pressure through the liquid, when the pressing process is over, and then the rubber envelope with billet body out of the container, this is a discontinuous forming method.

Isostatic molding has the following advantages over steel molding:

1. Can be formed with concave, hollow, slender parts and other complex shape parts

2. Low friction loss and high forming pressure

3. The pressure is transferred from all aspects, and the density of the billet is evenly distributed.

4. Low mold cost

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com