Molding Methods and Application of Polytetrafluoroethylene(PTFE)

Polytetrafluoroethylene (PTFE for short), commonly known as "the king of plastics", is a high molecular polymer prepared by polymerization of tetrafluoroethylene as a monomer. White waxy, translucent, excellent heat and cold resistance, can be used for a long time at -180~260ºC. This material is resistant to acid and alkali, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its friction coefficient is extremely low, so it can be used for lubrication, and it has also become an ideal coating for the inner layer of water pipes that are easy to clean.

PTFE mainly has common molding techniques such as molding, hydraulic pressure, pushing, extrusion, spraying, bonding, welding and winding. The first five are directly processed into products with PTFE resin, and the last three are processed into various products with PTFE plastic plates or thin strips. In addition, there are rolling methods, ripening methods and other forming methods. Now introduce several commonly used molding methods.

Molding method

1. Standard compression molding is to add powder or granular resin into a metal mold maintained at a certain temperature to make it plasticized, and fill the entire mold cavity under pressure, and then pressurize, cool, solidify and demould.

Hydraulic method

2. The hydraulic method, also known as the equal pressure method or the rubber belt method, is a special method for making PTFE products. It is to apply hydraulic pressure to the rubber belt to make the rubber belt expand the PTFE resin to the mold and compact it. Post-sintering molding.

Extrusion method

3. Extrusion molding can be divided into screw extrusion and plunger extrusion. The crushed and sieved pre-sintered resin is added to the material, and the raw material is compacted and conveyed by the rotation of the screw or the reciprocating push of the plunger. In the extruder, it is continuously extruded, sintered, and cooled at a temperature of 360-400°C to form various tube and rod products.

Adhesive method

4. The bonding method is to use the treatment liquid to destroy the C--F chain on the surface of PTFE, so that the F atoms are separated, leaving carbon atoms so that the surface can be bonded to the substrate with an adhesive.

Welding method

5. There are two welding methods, one is hot air welding with PFA welding rod; the other is to weld two PTFE plates together using a certain temperature and pressure.

Application field

The unique properties of PTFE make it widely used in industrial and marine operations such as chemical industry, petroleum, textile, food, papermaking, medicine, electronics and machinery.

1. Petroleum and chemical industry

Due to the defects in corrosion resistance of materials such as rubber, glass, and metal alloys, it is difficult to meet the harsh conditions of temperature, pressure, and coexistence of chemical media, and the resulting losses are quite alarming. With its excellent corrosion resistance, PTFE has become the main corrosion-resistant material in petroleum, chemical and other industries.

2. Papermaking, pharmaceutical, food, textile industries

Because the friction parts of some equipment are not suitable for lubricating with oil, for example, in the occasions where the lubricating oil will be dissolved by the solvent, or the products in the papermaking, pharmaceutical, food, textile and other industrial fields need to avoid lubricating oil contamination, which makes the filled PTFE Ethylene materials become the most ideal materials for oil-free lubrication (direct load bearing) of mechanical equipment parts.

3. Construction industry

Utilizing the low friction coefficient and high load-bearing capacity of PTFE in civil engineering and construction, it has been widely used in bridges, tunnels, steel structure roof trusses and other load-bearing sliders.

4. Electronic and electrical industry

The inherent low loss and small dielectric constant of PTFE materials make it possible to make enameled wires for micro motors, thermocouples, control devices, etc. PTFE film is an ideal insulating material for manufacturing capacitors, radio insulating gaskets, insulating cables, motors and transformers, and is also one of the indispensable materials for industrial electronic components such as aerospace.

5. Medical and pharmaceutical industry

The expanded polytetrafluoroethylene material is purely inert, has very strong biological adaptability, will not cause rejection by the body, has no physiological side effects on the human body, can be sterilized by any method, and has a microporous structure, so it can be used in a variety of Rehabilitation solutions, including artificial vessels and patches for soft tissue regeneration and surgical sutures for vascular, cardiac, general surgery and plastic surgery.

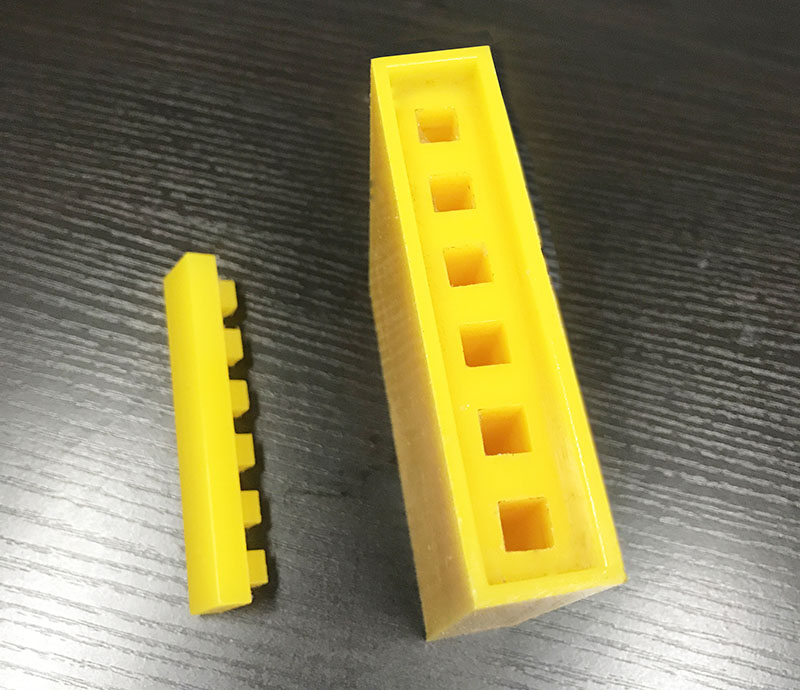

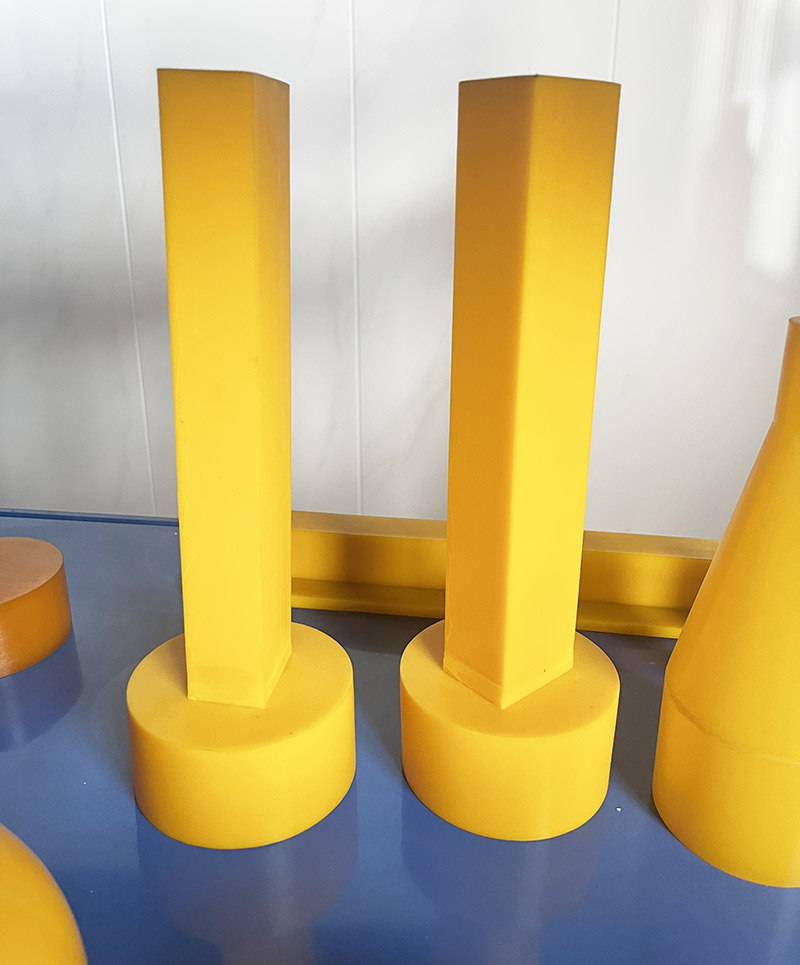

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com