Isostatic Pressing Process

The working principle of isostatic pressing technology is to put the pressed green body in a closed high-pressure cavity, the outer surface of the green body is covered with an elastic mold sheath, fill the high-pressure cavity with high-pressure liquid, apply a high pressure of hundreds of MPa, and the green body The body is subjected to uniform pressure in all directions and shrinks uniformly. After reaching the predetermined pressure and maintaining it for a certain period of time, a highly densified green body can be obtained. The green body after isostatic pressing has good strength and is convenient for machining. The compactness of the green body is good and uniform, and the mechanical properties are improved.

Compared with traditional dry pressing, isostatic pressing has the following advantages:

1. The green body has a higher density, which is generally about 10% higher than that of dry pressing.

2. It can make blanks with large size or complex shape.

3. The green body has good strength, which is convenient for handling and direct machining.

4. The density of the green body is uniform in all directions, and the internal stress of the green body is small, which reduces defects such as cracking and delamination of the green body, and the deformation of the sintered product is small.

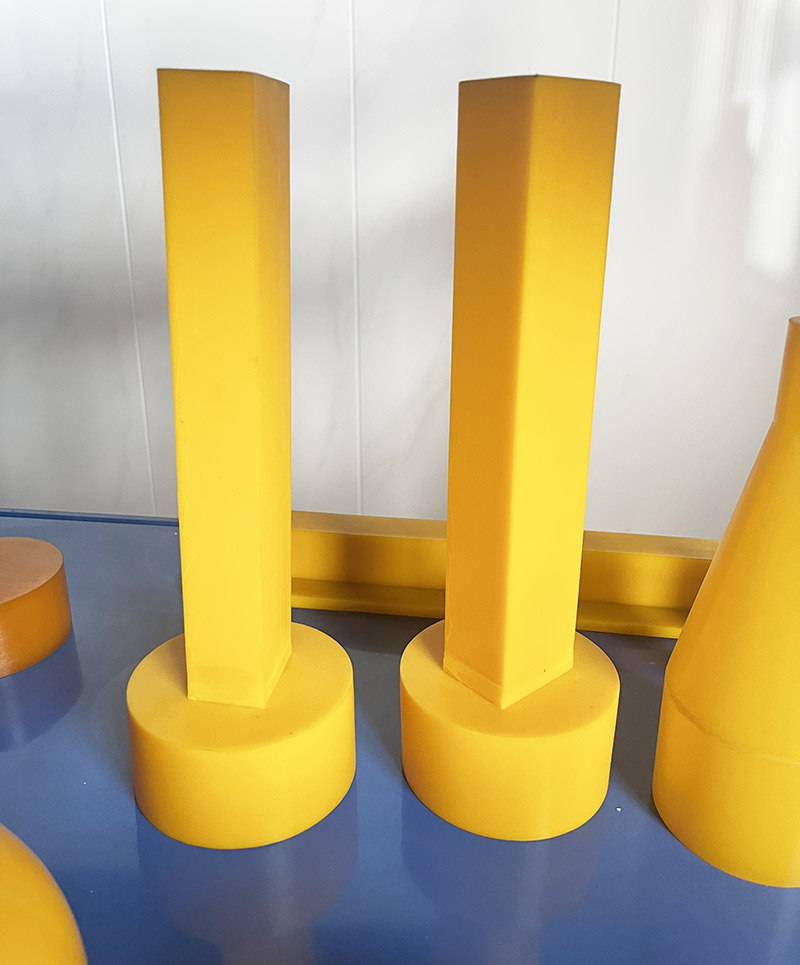

The pressurized rubber mold of the dry bag isostatic pressing process is fixed in the cylinder body in advance. After the powder is loaded into the forming rubber mold, they are put into the pressurized rubber mold together, or the powder is sent to the pressurized rubber mold through the feeding hopper from above. Since the forming rubber mold is not in contact with the liquid medium, it is called the dry bag method. According to the introduction, different from the wet bag method, the dry bag method can realize continuous operation - when charging, the upper cover is opened, the material is loaded from the hopper, then the upper cover is closed, and pressurized; The upper cover is opened, and the blank is ejected from the top through the top rod at the bottom. In this way, the dry bag method has a high degree of automation and a short operating cycle, which is suitable for mass production. However, it also has certain limitations. Since the pressurized rubber mold is not easy to be replaced frequently, the size and shape of the product will be limited to a certain extent. It is most suitable for the preparation of rod and tubular ceramic products.

Wet bag isostatic pressing is to enclose the billet (or pre-pressed in advance) in an elastic isostatic mold, put it into a high-pressure cylinder after sealing, and press the billet to form it through liquid transfer. This method can change the shape and size of the plastic sheath, the product has great flexibility, and is suitable for small-scale production. However, manual bagging and unloading operations are required every time, and the production efficiency is not high. This method is mainly used for the production of large and special-shaped parts.