The Types and Advantages of Cold Isostatic Pressing

Types of cold isostatic pressing:

Wet bag process: IN this, the mould is directly in contact with the fluid. This reduces the productivity, since the bag has to be removed every time before refilling. Tooling costs are reduced in this.

Fixed mould process: the mould is fixed in the pressure vessel and powders are filled in situ. The tooling has internal channel into which fluid is pumped. This is an automated process in which the powder filling, compaction, depressurization and removal of green parts are done continuously. This involves higher tooling cost, but has higher production rate.

Advantages of CIP:

Uniform, controlled, reproducible densification of powder; long, slender parts can be pressed; neat net shape forming; short production times; economy of operation for complex and large parts.

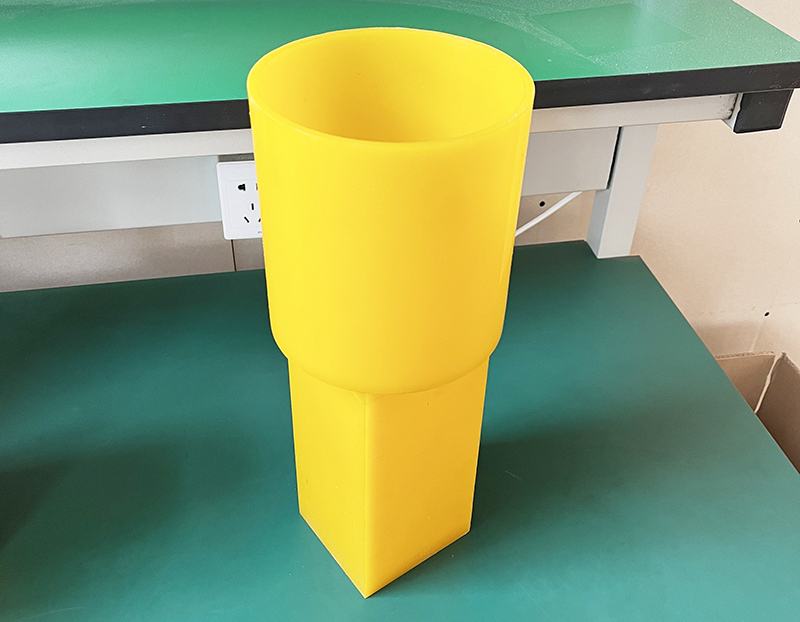

Applications:

Metallic filters made from bronze, brass, stainless steel, Inconel, Monel, Titanium, high speed tools, carbide tools. Also ceramic parts such as sparks plugs and insulators are made by this method.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com