Cold Isostatic Pressing- CIP

Cold isostatic pressing(CIP) applies pressure from multiple directions for achieving greater uniformity of compaction (high-quality parts) and increased shape capability, compared to uniaxial pressing.

There are two methods of carrying out isostatic pressing.

In wet-bag isostatic pressing –

Powder is encased in a rubber sheath that is immersed in a liquid which transmits the pressure uniformly to the powder.

In dry-bag isostatic pressing –

Rather than immerse the tooling in a fluid, the tooling itself is built with internal channels into which high-pressure fluid is pumped.

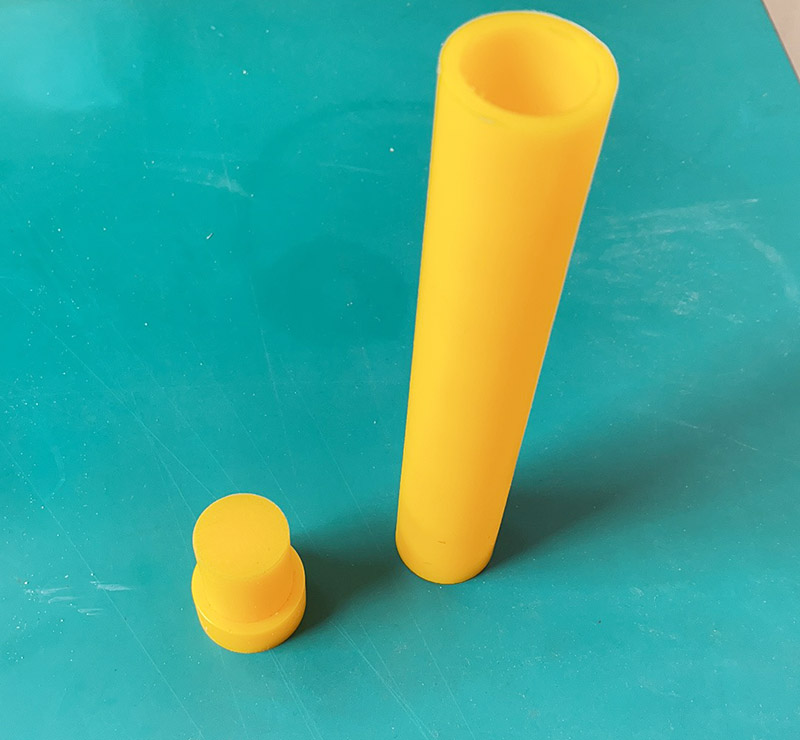

The cold isostatic press is also known as a rubber press.

Ceramic powder and metal powder fill a rubber mold, which is then dipped into the pressure vessel.

The powder is compressed at a maximum water pressure of 400 MPa.

Isostatic actions (hydrostatic pressure) can also form complicated shapes which cannot be compressed without a uniaxial press or machine press.

Applications

Powder forming of refractory, insulator, isotropic graphite, high-melting-point metals, cemented carbides, tool steel, sintered filters, artificial bones, resin powder, food processing etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com