Isostatic Pressing Technology

Isostatic pressing is a relatively new development for powder metallurgy. In isostatic pressing, prepared metal powder is placed inside a flexible mold. A vacuum is created in the mold and it is then sealed. The mold along with the powder is then placed in a pressurized chamber into which a gas or oil is pumped through the chamber to generate pressure 3000 kg-f / cm2 or more. The pressure compresses the powder from all direction to give it the required shape.

There are two types of Isopressing ; (1) Cold Isostatic pressing (CIP) and (2) Hot Isostatic Pressing (HIP).

In CIP, the metal powder is placed in a elastomeric material (an elastomer posses rubbery qualities such as high resilience and extensibility) and high pressure is applied at room temperature inside the pressure chamber. Water or oil is the pressure medium. The parts are removed and sintered.

In HIP, the pressure is generated by an inert gas like helium or argon. The gas is reclaimed after every charge. However , in both the methods tooling cost is high in comparison to die-compacting method.

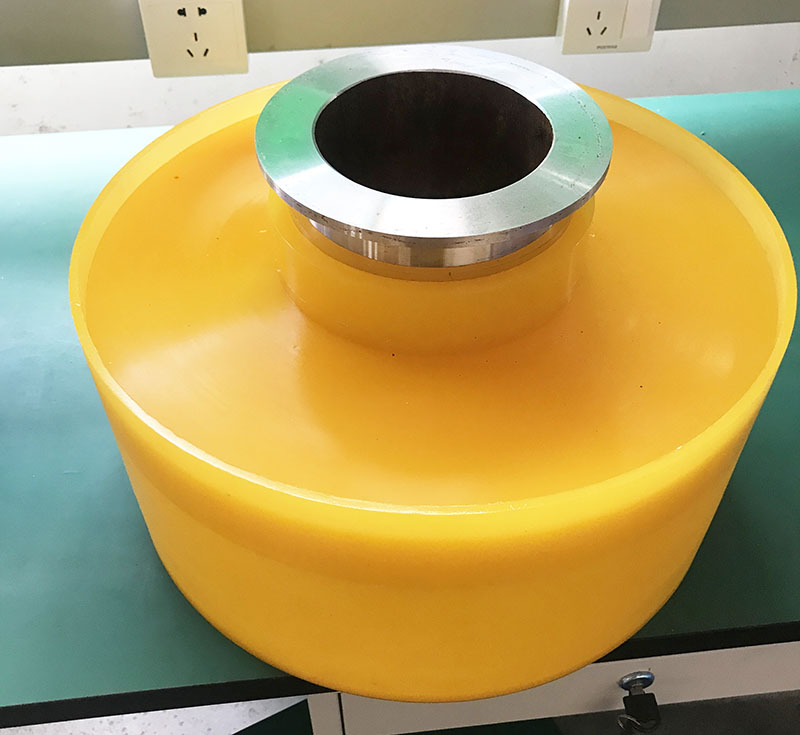

Zirconia ceramic cold isostatic pressing referred to as isostatic pressing (CIP), acts as the static pressure produced by fluid or gas directly on the powder or blank in the elastic die sleeve through a high-pressure pump, so that it is pressed by isotropic uniform pressure.

Isostatic pressing technology can be used to make new alloy products that are difficult to be produced by casting technology, and it is also a very good forming process for zirconia ceramic products and alumina ceramic products with high performance and strength requirements.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com