CIP- Cold Isostatic Pressing

CIP, Cold Isostatic Pressing, is one of material processing methods. It makes use of the principle "A change in the pressure of an enclosed incompressible fluid is conveyed undiminished to every part of the fluid and to the surface of its container." proposed by the French scientist Blaise Pascal.

What is the pressure used in cold isostatic pressing CIP?

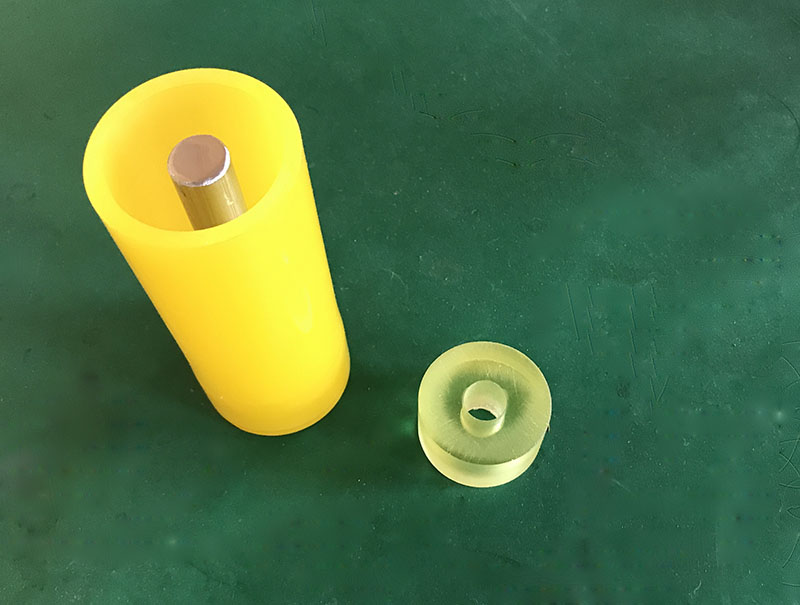

Isostatic pressing (cold isostatic pressing) consists in compacting a powder in an elastomeric container submersed in a fluid at a pressure of 20 to 400 MPa.

Does cold isostatic pressing require sintering afterwards?

Cold isostatic pressing is a method of compacting powdered materials into a solid homogeneous mass before machining or sintering. ... It is found that the dry bag isostatic pressing process lends itself to automation and is therefore suited for pressing relatively long runs of compacts at high production rates.

How does an isostatic press work?

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. ... The adsorbed gases are removed with high heat and the remaining material compressed to full density using argon gas during the heat cycle.

What is uniaxial pressing?

Uniaxial pressing (dry or die pressing) is the most common method of compaction to form PM components. This low-cost process is adapted to high- volume (up to few hundreds of parts per minute) production of 'relatively simple' geometry powder compacts.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com