Classification and Characteristics of Isostatic Pressing

Isostatic pressing is to place the sample to be pressed in a high-pressure container, and use the incompressible properties of the liquid medium and the property of uniformly transmitting pressure to uniformly pressurize the sample from all directions. When the liquid medium is injected into the pressure container through a pressure pump , according to the principle of fluid mechanics, its pressure is constant and uniformly transmitted to all directions. At this time, the pressure of the powder in the high-pressure container in all directions is uniform and consistent in size. The method of forming a dense body from barren powder by the above method is called isostatic pressing.It includes the stage of migration and re-accumulation of powder particles when the initial molding pressure is small; the stage of local flow and fragmentation of the powder when the pressure is increased in the middle stage; and the stage of densification when the pressure of the powder is maximum in the later stage, and the pores are discharged to reach the densification stage.The pressure transmitted by the liquid medium during isostatic pressing is equal in all directions. The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the green body is uniformly stressed, the density distribution is uniform, and the product performance is greatly improved.Isostatic pressing products have outstanding advantages such as uniform structure, high density, small sintering shrinkage, low mold cost, high production efficiency, complex shapes, slender products, large-size products and precision-size products. Advanced molding technology, with its unique advantages, began to replace traditional molding methods, such as spark plugs, ceramic balls, plungers, vacuum tube shells and other products produced by ceramics, showing more and more broad application prospects.

There are two types of isostatic pressing methods: cold isostatic pressing and hot isostatic pressing. Cold isostatic pressing is divided into wet isostatic pressing and dry isostatic pressing.

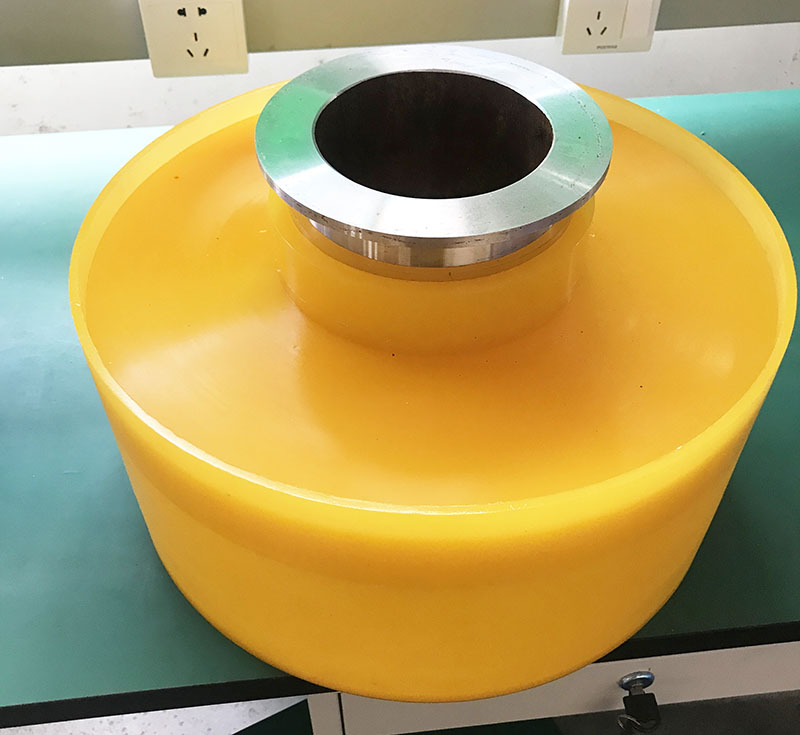

The process can be summarized as first filling the powder into the rubber sleeve of the applicable product size, and then placing the rubber sleeve in a high-pressure container, using the incompressible properties of the liquid medium and the property of uniform pressure transmission to uniformly press the rubber sleeve from all directions, The pressure is about 200 tons.

When the liquid medium is injected into the pressure container through the pressure pump, according to the principle of fluid mechanics, its pressure is constant and uniformly transmitted to all directions. At this time, the powder in the high-pressure container is subjected to pressure in all directions. are uniform and consistent in size.

The method of forming a dense body from the ceramic powder by the above method is called isostatic pressing. Simply put, the blank is formed by placing the mold in a high-pressure vessel, sealing it, and applying pressure to the mold.

Isostatic pressing is mostly used for the production of some simple and large-scale ceramic products. The ceramics formed in this way have uniform density, are not easily deformed by sintering, and have high quality of formed ceramics.

1.The isostatic pressing method has the following characteristics

It can form simple, large and thin and long products that cannot be produced by ordinary methods, and the forming quality is high.

The molding pressure can be easily increased without increasing the difficulty of operation, and the pressure effect is better than other dry pressing methods.

Since the green body is uniformly pressured in all directions, its density is large and uniform, and the firing shrinkage is small, so it is not easy to deform.

The mold is easy to make, has a long life and low cost.

Less or no binder can be used.

2.The advantages and disadvantages of isostatic pressing

Advantages: high density, good quality, can be formed in large quantities

Disadvantages: high cost, unable to make special shapes

3.The operation process of isostatic pressing equipment is as follows

First, put the prepared blank into an elastic mold made of plastic or rubber, place it in a high-pressure container, and after sealing, inject a high-pressure liquid medium, and transfer the pressure to the elastic mold to add jade to the blank.

The pressure is then released to remove the mold, and the formed blank is removed from the mold.

The liquid medium can be water, oil or glycerol. However, it is appropriate to use a medium with low compressibility, such as brake oil or anhydrous glycerin. The elastic mold material should be rubber or similar plastic with good elasticity and oil resistance.