Characteristics and classification of isostatic pressing

The isostatic press is to place the product in a closed container filled with liquid. After electrification, the pressure exerted by the liquid on each surface of the sample is equal. Under the high pressure environment, the density of the product becomes larger and the gap between the sample particles becomes smaller and get the desired shape.

1.The Characteristics of isostatic pressing

The main features of isostatic pressing are:

(1) The density distribution of the extruded green body is relatively uniform, and the internal structural defects are less;

(2) Green bodies with controlled bulk density can be produced, and the pressure in the isostatic high-pressure vessel is proportional to the density of the green bodies;

(3) Since the pressure in the high-pressure vessel is much higher than that of general molding, green compacts with higher bulk density can be prepared, and even binderless molding of petroleum coke powder can be performed;

(4) It can produce green bodies with complex shapes, such as spherical or tubular green bodies can be directly pressed;

2.The classification of isostatic pressing

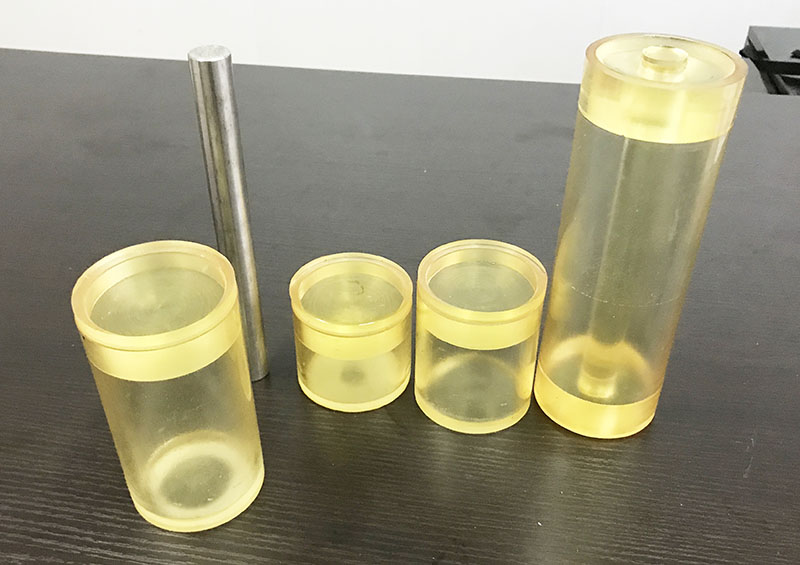

a) Dry isostatic pressing is relatively speaking, that is, the molds are not all in a high-pressure liquid medium, but semi-stationary, so that the addition of blanks and the removal of blanks are operated in a dry state. Dry isostatic pressing is quasi-isostatic pressing, and its compression molding bag can be made of nitrile rubber or ether urethane. When the dry mold bag is pressed and clamped by the upper and lower punches, the high-pressure liquid is input into the surrounding of the dry mold bag, so that the ceramic powder is formed by uniform pressure. Dry isostatic presses can be made into automated continuous presses suitable for mass production.

b)The main structure of wet isostatic pressing is to encapsulate the pre-pressed blank in an elastic rubber mold or plastic mold, and then place it in a high-pressure container, which is filled with liquid medium. The formed body is in a high-pressure liquid, and all sides are evenly pressed, so it is called wet isostatic pressing. After pressurization, the pressure can be released, the upper cover head is opened, the mold is taken out, and the formed blank is taken out from the mold.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com