What is the production process of alumina ball?

1. Extrusion forming alumina ball

Extrusion forming alumina porcelain ball is the current similar porcelain ball of lower grade, but also a larger production of a forming method, generally used for forming aluminum ceramic ball or clay ball. This kind of porcelain ball sintering temperature is low, simple equipment, small investment, only need to have the ball mill, filter press, vacuum mud machine, low temperature kiln can be. The forming method is to extrude mud strips with vacuum mud machine or hydraulic extruder, according to different specifications of the ball stone cut into different mud sections with artificial or mechanical rubbing into a ball, and then dry the ball blank.

2. Pellet forming alumina porcelain ball

Alumina porcelain ball forming by pellet method is to learn from the process of Zhongcheng pill or northern forming dumplings, which belongs to a semi-wet and dry forming method. It is formed by sticking dry powder on the outside of the "wet core" constantly. This forming method determines the low density of the billet body, the billet body has stratification, easy to spalling when grinding, poor impact resistance. Its forming equipment is relatively simple, only a set of pellet machine can be.

3. Hydraulic hard die forming alumina grinding ball

Strictly speaking, the alumina grinding ball formed by this method is not spherical in the geometric sense, but cylindrical or column spherical, using this forming method is generally more than aluminum porcelain ball. The forming method has higher requirements on powder, and the powder generally needs spray granulation. According to different specifications and output requirements using different equipment, early small batch and even useful hydraulic jack to form alumina porcelain ball, with the fierce competition in the industry, this way has been gradually eliminated. Activated carbon alumina ball forming with single column hydraulic press is used more in the past, its equipment investment is small, buy standard single column hydraulic press, self-matching ejector cylinder demudding. With this method of forming, the general forming pressure is not high, and is one-way pressure, the billet body strength is low, the density is small, burning shrinkage, sintering temperature is high. Forming activated carbon alumina balls with bidirectional hydraulic press is a recent development, especially suitable for forming balls.

4. Wet bag method cold isostatic pressing inert alumina porcelain ball

The inert porcelain ball is formed by cold isostatic pressing with wet bag method. The powder is first filled in the soft mold (rubber mold) with spherical inner cavity. The soft mold should be sealed well and put into the working cylinder (high pressure container) of the cold isostatic press, and the ultra-high pressure (generally in 1oompa) Above) liquid medium, liquid medium with equal pressure to the soft mold and powder evenly compressed, after pressure relief will be the soft mold together with its internal blank body from the cold isostatic press cylinder out of the work (plastic mold is wet, and plastic mold is also known as the bag, wet bag from this name), in the working cylinder is released to get spherical blank body. The alumina porcelain ball formed by this method has high density and uniformity, which is better than other forming methods.

5. Dry isostatic pressing forming high alumina porcelain ball

High alumina porcelain ball forming by dry isostatic pressing is a better forming method at present, which is easy to realize automation and less affected by human factors. The consistency of the shape and appearance of the blank body is better than that of cold isostatic pressing by wet bag. Generally, from the beginning of pressure to the end of a pressing cycle in one minute, pressure relief when the gas inside the body to discharge in a short time, if the powder water is not uniform or the granularity of granulation is not appropriate, the body is easy to crack or even pulverized burst, so this method of forming the forming performance of the powder is high, must be sprayed by the powder granulation.

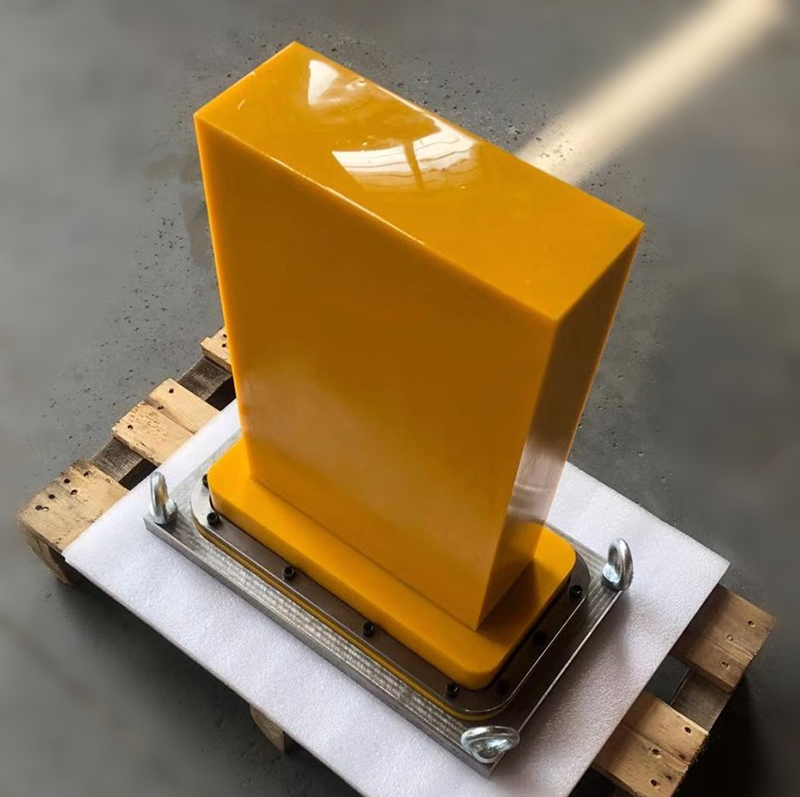

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com