Alumina Ceramic and Cold Isostatic Pressing

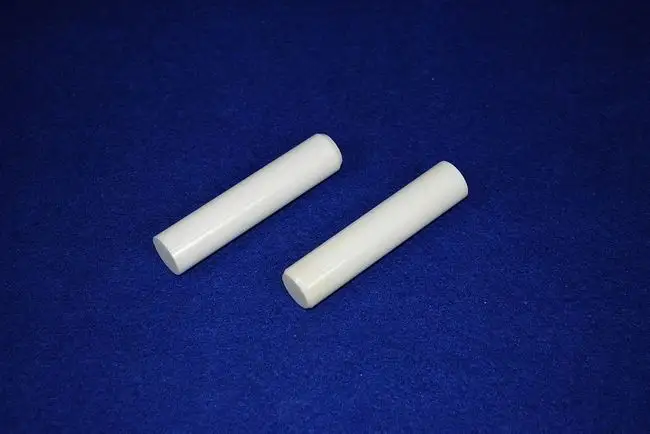

Alumina ceramic has the advantages of high insulation, high heat insulation, corrosion resistance, high hardness, can be widely used in the manufacture of crucible, engine spark plug, high temperature refractory materials, thermocouple sleeve, insulation substrate, sealing ring, tool mold and so on.

Pores are common in ceramic materials, and the densification process of ceramics is actually a process of decreasing pores. According to different sintering processes, pores often remain in the interior of ceramic materials in two ways, one is in the ceramic grain, the other is in the grain boundary.

Therefore, it is generally believed that there are two main ways to improve the density of alumina ceramics. First of all, by increasing the sintering temperature or providing reduction atmosphere, so that the ceramic under high temperature conditions, atoms are easy to diffuse to achieve sintering, at the same time, the gas phase of the ceramic is easy to diffuse out of the grain and sintering into dense ceramics; Secondly, it is to improve the compactness of ceramics through additives.

Molding is one of the important processes that directly affect the sintering process and the properties of sintered body. The experiment verifies that under the same sintering temperature, the relative density of the blank is higher, so is the relative density of the sintered body. Therefore, in order to ensure higher density, the general molding pressure is larger. At present, high performance alumina ceramic molding methods are divided into dry method and wet method two types.

1. Dry molding

In dry molding, we will first think of cold isostatic molding, isostatic molding is the aluminum oxide powder into an elastic mold sealed, and then put the mold into a high-pressure gas or liquid container. After sealing, the powder is pressed into a high density green blank with the characteristic of three-dimensional force equality. The main forming method of high - pressure sodium lamp is isostatic pressing.

In order to further improve the density of the forming body, high pressure forming and ultra-high pressure forming have been developed on the basis of the ordinary isostatic pressing forming, using these two forming methods to prepare relatively high density ceramic billets.

2. Wet molding

In recent years, wet forming has developed rapidly because of its ability to control the agglomeration of particles and the content of impurities in the billet, reduce the defects of the billet and form the ceramic parts with complex shapes. Such as centrifugal grouting molding, is to adjust the pH value and other means to make the powder evenly dispersed in the liquid, and then high-speed centrifugal particle settlement to obtain green. There are direct gel molding of powder preparation and molding process in one go, as well as by organic monomer polymerization to complete the billet solidification of gel casting molding and by chemical potential molding of penetration curing method, these methods have been in the synthesis of some nanomaterials have been very good application.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com