Precision Forming Processes of Zirconia Ceramics

Dry forming

1 Dry Press Molding

Dry pressing uses pressure to press ceramic powder into a green body of a certain shape. Its essence is that under the action of external force, the powder particles are close to each other in the mold, and are firmly combined by internal friction to maintain a certain shape. The main defect in the dry-pressed green body is lamination, which is due to the internal friction between the powder and the friction between the powder and the mold wall, resulting in pressure loss inside the green body.

The advantages of dry pressing are that the size of the green body is accurate, the operation is simple, and it is convenient to realize mechanized operation; the content of moisture and binder in the dry pressing green body is less, and the drying and firing shrinkage is smaller. It is mainly used to form products with simple shapes, and the aspect ratio is small. The increased production cost caused by mold wear is the disadvantage of dry pressing.

2 Isostatic Pressing

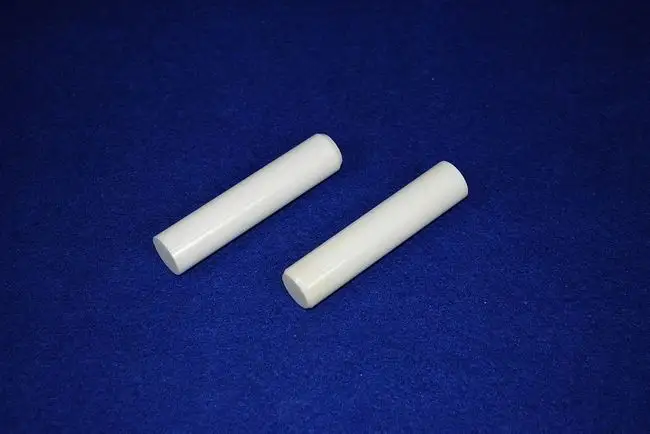

Isostatic pressing is a special forming method developed on the basis of traditional dry pressing. It uses fluid to transmit pressure to apply pressure evenly to the powder in the elastic mold from all directions. Due to the consistency of the internal pressure of the fluid, the pressure on the powder in all directions is the same, so the difference in the internal density of the green body can be avoided.

Isostatic pressing can be divided into wet bag isostatic pressing and dry bag isostatic pressing. Wet bag isostatic pressing can form products with complex shapes, but it can only be operated intermittently. Dry bag isostatic pressing can realize automatic continuous operation, but it can only form products with simple shapes such as square, round, and tubular cross-sections. Isostatic pressing can obtain a uniform and dense green body, with small firing shrinkage and uniform shrinkage in all directions, but the equipment is more complicated and expensive, and the production efficiency is not high, so it is only suitable for the production of materials with special requirements.

Wet Forming

1. Grouting

The grouting molding process is similar to the tape casting molding, the difference is that the molding process includes a physical dehydration process and a chemical coagulation process. The physical dehydration removes the moisture in the slurry through the capillary action of the porous plaster mold. The chemical coagulation process is due to the The Ca2+ produced by the dissolution of surface CaSO4 increases the ionic strength in the slurry, resulting in flocculation of the slurry.

Under the action of physical dehydration and chemical coagulation, ceramic powder particles are deposited on the plaster mold wall. Slip casting is suitable for preparing large ceramic parts with complex shapes, but the quality of the green body, including shape, density, and strength, is poor, and the labor intensity of workers is high and it is not suitable for automated operations.

2 Hot Die Casting

Hot die casting molding is to mix ceramic powder and binder (paraffin wax) at a relatively high temperature (60~100°C) to obtain a slurry for hot die casting. The slurry is injected into a metal mold under the action of compressed air, and the pressure is maintained. Cooling, demoulding to obtain a wax base, the wax base is dewaxed under the protection of inert powder to obtain a green body, and the green body is sintered at high temperature to become porcelain.

The green body formed by hot die casting has precise size, uniform internal structure, less mold wear, high production efficiency, and is suitable for various raw materials. The temperature of the wax slurry and the mold needs to be strictly controlled, otherwise it will cause underfilling or deformation, so it is not suitable for manufacturing large parts. At the same time, the two-step firing process is more complicated and consumes more energy.

3 Tape Casting

Tape casting is to fully mix ceramic powder with a large amount of organic binder, plasticizer, dispersant, etc. to obtain a flowable viscous slurry, put the slurry into the hopper of the casting machine, and use a scraper to control the thickness. It flows out to the conveyor belt through the feeding nozzle, and the film blank is obtained after drying.

This process is suitable for the preparation of thin film materials. In order to obtain better flexibility, a large amount of organic matter is added, which requires strict control of process parameters, otherwise it will easily cause defects such as peeling, streaks, low film strength or difficult peeling. The organic substances used are toxic and will cause environmental pollution. Non-toxic or less toxic systems should be used as much as possible to reduce environmental pollution.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com