Ceramic Targets

With the development of the electronics industry, high-tech materials are gradually transferred to thin films, and the coating period develops rapidly. The target is a special electronic material with high added value and is the source of sputtering thin film materials. As the basic material for the development of non-metal thin film industry, ceramic targets have achieved unprecedented development, and the target market is expanding day by day.

Types of ceramic targets:

(1) According to the application, it can be divided into semiconductor-related ceramic targets, display ceramic targets, magnetic recording ceramic targets, optical recording ceramic targets, superconducting ceramic targets, giant magnetoresistance ceramic targets, etc.

(2) According to the chemical composition, it can be divided into oxide ceramic targets, silicide ceramic targets, nitride ceramic targets, fluoride ceramic targets and sulfide ceramic targets. Among them, the planar display ITO ceramic target has been widely produced and applied in China. Ceramic targets for high dielectric insulating films and giant magnetoresistance ceramic targets have broad application prospects.

The characteristic requirements of ceramic targets:

(1) Purity: The purity of the ceramic target has a great influence on the performance of the sputtered film. The higher the purity, the better the uniformity of the sputtered film and the consistency of the mass product quality. Over the past few years, with the development of the microelectronics industry, the requirements for the uniformity of the film forming area are very strict, and its purity must be greater than 4N. The purity of ITO targets In2O3 and Sn2O3 for planar display is greater than 4N.

(2) Density: In order to reduce the pores of the ceramic target and improve the performance of the film, the sputtering ceramic target is required to have a high density. The denser the target, the lower the density of sputtering particles, the weaker the discharge site and the better the performance of the film.

(3) Uniformity of composition and structure: In order to ensure the uniformity of the sputtering film, UTEC must achieve good target composition and structure uniformity in complex large-area coating applications.

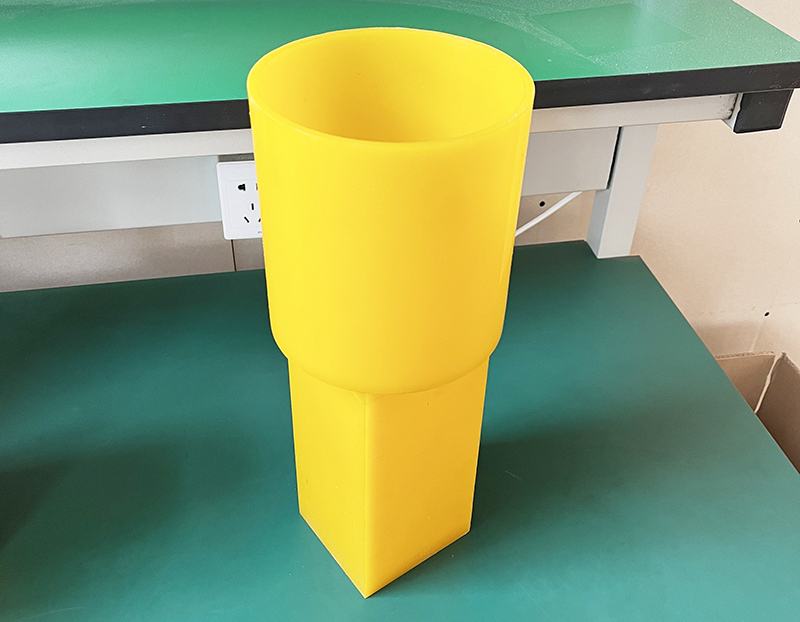

For the preparation of sputtering ceramic targets, commonly used molding methods include dry pressing, cold isostatic pressing, etc. Cold isostatic pressing has become the most commonly used forming method because of its advantages such as high and uniform green body density, convenient abrasive tool making, and low cost. The sintering of ceramic targets often adopts methods such as atmospheric pressure sintering, hot pressing sintering and atmosphere sintering.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com