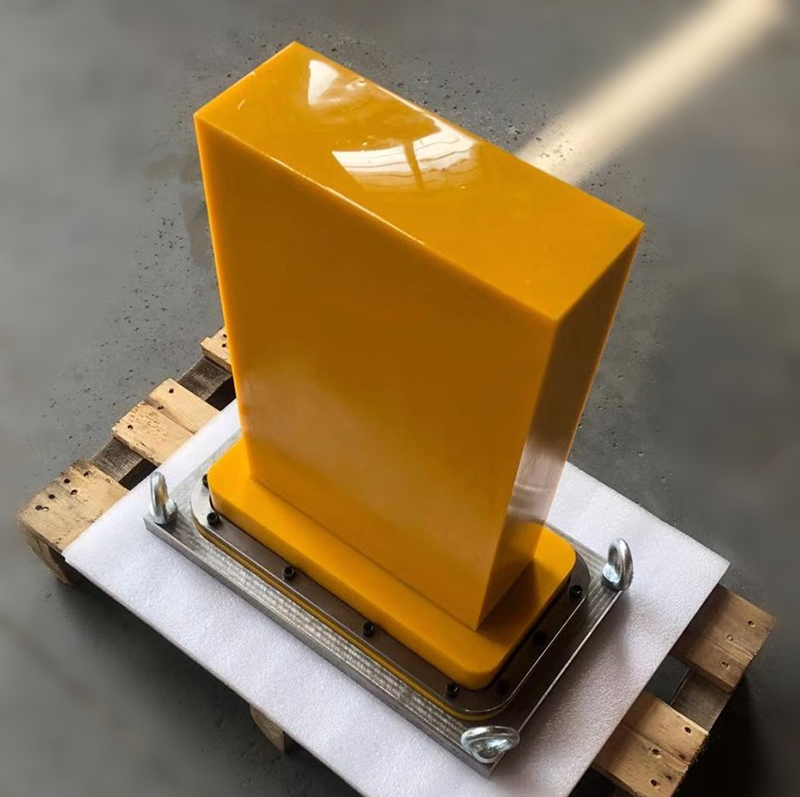

Isostatic Pressing Bags, molds

In the cold isostatic pressing technology, the reasonable design of the jacket and the mold is the key to ensure the quality of the compact and improve the service life of the jacket, and it is also an important factor to save raw materials and reduce costs.

Cold isostatic pressing is to rely on the mold cavity formed by the mold components to fill the powder. After sealing, under the action of external pressure, the volume of the cavity filled with powder bundles is reduced through the displacement or deformation of the module. So as to achieve the purpose of compressing powder and forming powder. The shape and size of the mold cavity are directly related to, or basically similar to, the shape and size of the compact after molding. The complexity of the mold is related to the desired shape of the compact.

In the cold isostatic pressing forming technology, according to the different forming methods. Covers and molds are divided into package molds for wet bag method, dry bag method, and balanced pressing method. No matter what kind of mold, it is composed of four basic components: plastic mold, rigid mold, port sealing device and support device.

The cover, end plug and mold pad of the plastic mold are made of materials such as rubber or plastic. In cold isostatic pressing, the plastic mold not only plays the role of mold, but also plays the role of transmitting pressure to make the powder compact.

The core and mold of the rigid mold are made of metal materials, and the size and shape of the rigid mold remain unchanged during the molding process.

The port sealing device can be designed in different forms according to the shape and size of the compact. For example, the port device of forming a cylindrical compact, the common sealing methods are; rubber plug seal; rubber plug plus sheath seal; sheath cover plus elastic ring seal; elastic sheath cover self-sealing; sheath cover rigid ring binding seal ; Rigid self-tightening and binding sealing of elastic sheath cover, etc.

Due to the thinness of the sheath, it is difficult to maintain the fixed shape of the sheath after loading when deoxidizing the powder in the sheath, so a special support device needs to be attached outside the sheath. This device can be divided into fixed type and random type.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com