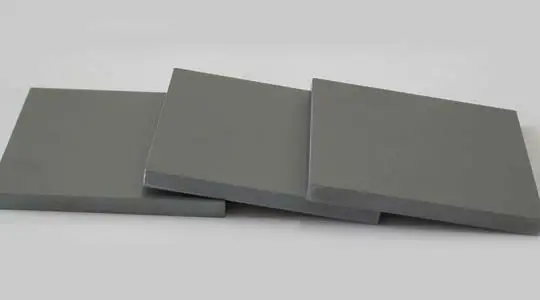

ITO Target

The ito target is a black-gray ceramic semiconductor formed by mixing indium oxide and tin oxide powder in a certain proportion after a series of production processes, and then sintering in a high-temperature atmosphere (1600 degrees, sintering with oxygen). The ito thin film uses the ito target as the raw material, and the ito target is vaporized and sputtered onto the glass substrate or flexible organic film by magnetron sputtering.

The ito target is mainly used in flat panel displays, and the target is mainly used in semiconductors. The rapid development of science and technology has allowed the electronics industry to occupy a large share of the market, directly affecting people's work and life.

The ito target has extremely high performance advantages, and has relatively high thermal shock resistance, which will not cause damage to the equipment during use, and its purity is particularly high. At present, many electronic products in the market use flat-panel displays. Computers and TVs have entered thousands of households. LCD products are relatively high in appearance and texture, and can reduce energy consumption.

Ito targets are widely used in the electronics field, because the requirements for materials in the electronics field are generally relatively high. It plays a certain role in promoting the development of the electronics industry. At the same time, the target material can prolong the service life of electronic products, and the quality is relatively in line with the testing standards. Generally, the output is rarely unqualified, and at the same time, it can also meet the requirements in appearance. people's demands.

The main four methods of forming the ITO target are:

1. Spraying method.

The spraying method is to use high-pressure gas (N2, H2, mixed gas or air) to carry powder particles through the zoom tube to generate supersonic two-phase flow, hit the substrate in a solid state, and deposit on the surface of the binding backplane through large plastic flow deformation. A coating is formed, and the coating is thickened layer by layer to obtain a ceramic target.

2. Cold isostatic pressing

The cold isostatic pressing method is to put the pre-formed blank into the rubber sheath and immerse it in the high-pressure liquid to make it bear isotropic pressure, so as to realize the strengthening of the density of the green blank. Cold isostatic pressing is only to obtain the green body with the highest possible density, which makes the sintering and densification of the green body easier. Since cold isostatic pressing does not have the sintering ability of hot isostatic pressing, an independent sintering process is required to fire the green body.

3. Hot isostatic pressing

It is to put the powder or the pre-pressed blank into the package, then vacuumize the inside of the package, weld and seal it, put it in a high-pressure container, and make the powder sinter under high temperature and equal pressure, and the forming and sintering are carried out at the same time.

In the development of ITO targets, it is difficult to obtain high-density and large-size materials by the hot isostatic pressing technology adopted in the early stage. With the emergence of the atmospheric pressure sintering method, the target material prepared by the hot isostatic pressing method is small in size, low in density, high in oxygen loss rate, expensive in equipment and high in cost, making hot isostatic pressing in The preparation of ITO ceramic targets does not have a competitive advantage, and subsequent research and industrialization are gradually downplayed by the industry, but it is still more suitable for ceramic targets that require oxygen deficiency.

4. Wet forming

Wet forming is to prepare the oxide powder into a slurry, and then achieve a specific shape of the green body by self-solidification, water absorption or pressure filtration, etc., and obtain a high-density green body after drying. Wet forming can not only realize the function of cold isostatic pressing, but also make up for the deficiency of cold isostatic pressing. Wet molding of ceramic targets includes grouting molding, colloidal molding, direct solidification molding, etc.

Cold isostatic pressing molds/bags/toolings