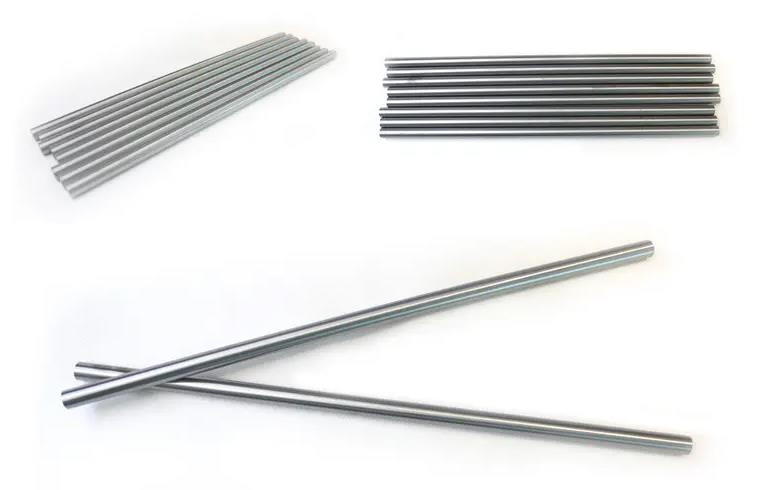

Tungsten Rod

Tungsten rod, also known as tungsten alloy rod. Tungsten alloy rod (WMoNiFe) and Anviloy 1150 are made of metal powder at a specific high temperature, using a special high-temperature powder metallurgy technology. In this way, the tungsten alloy rod material has low thermal expansion coefficient, good thermal conductivity and good material properties.

At high temperature, tungsten alloy rod is used as a material with high melting point and low thermal expansion coefficient. The addition of tungsten alloying elements improves machinability, toughness and weldability.

Due to its unique wear resistance, high hardness, excellent fracture toughness and compressive strength, cemented carbide rods are widely used in metal processing, electronics, wood processing, aerospace, medical and other industries. Ideal precursor material for drills, milling cutters, reamers, ladder knives, rod cutters, taps and dot matrix printer pins. With the development of science and technology, the demand for cemented carbide rods is increasing day by day, and its forming process has been developed from traditional cold isostatic pressing, molding and other processes to more modern and economical extrusion forming processes, and the product quality is better. More variety.

Traditional processes can be divided into cold isostatic pressing (CIP) and molding processes. Although it is rarely used, it is essential in some specific occasions. The CIP process of cemented carbide bar forming mainly includes pressing method, wet bag method and dry bag method.

Cold Isostatic Pressing Bags/Molds/Toolings

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com