There are four main forming methods for ITO targets

Vacuum hot pressing--The vacuum hot pressing method is a process of densifying ceramic materials using thermal energy and mechanical energy, which can produce high-density ITO ceramic targets with a density of 91% to 96%. The process is as follows: heat the mold, add the sample, fix the model on the heating plate (control the melting temperature and time), then melt the sample, harden, cool and finally take out the finished product.

Hot isostatic pressing - hot isostatic pressing (HIP) can be considered as pressure sintering or high temperature pressing. 0.5~0.7 times) to make the material completely dense. It can control the structure well, suppress the grain growth and obtain a uniform and isotropic structure. The process of preparing ITO targets by hot isostatic pressing is as follows: First, the ITO solid solution powder is partially reduced in a certain reducing atmosphere (such as a mixture of H2, N2 and H2) and at a temperature of 300~500 °C. Then, by molding Or cold isostatic pressing to press the reduced powder into preforms, the preforms are placed in a stainless steel container with insulating material between them. Then the container is evacuated and sealed. Finally, the container is put into 800~1050℃ 50~ The ITO target was prepared in a 200MPa hot isostatic pressing furnace for 2 to 6 hours.

Room temperature sintering - room temperature sintering is a target preparation method developed in the early 1990s. It adopts the pre-pressing method (or slurry casting method) to prepare high-density target preforms, and then sinters them in a certain atmosphere and temperature. The main process of normal pressure sintering method is: mix In2O3 powder (with a certain tap density) and SnO2 powder to prepare a slurry for slurry casting, and then dehydrate for a long time at a temperature of 300~500 °C Degreasing treatment, and finally sintering at 1450 to 1550 °C at a pressure above 1 atmosphere in pure oxygen or air atmosphere.

Cold isostatic pressing - Cold isostatic pressing (CIP) uses rubber or plastic as the covering mold material at room temperature, and uses liquid as the pressure medium to transmit ultra-high pressure. Under the protection of a low-pressure oxygen atmosphere, the ITO powder was pressed into a large ceramic preform by cold isostatic pressing, and then sintered at a high temperature of 1500-1600 °C in a pure oxygen environment of 0.1-0.9 MPa. The theory of this method It can produce ceramic targets with a density of 95%.

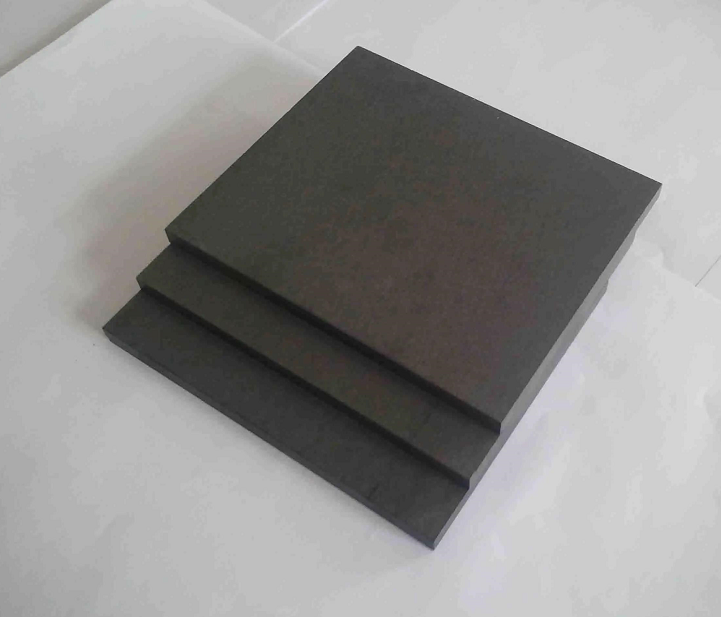

Cold Isostatic Pressing Bags/Molds/Toolings

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com