Introduction to HIP (Hot Isostatic Pressing)

Hot Isostatic Pressing is a manufacturing technique designed to increase the density of materials by reducing or eliminating their porosity or microporosity thus creating fully dense ‘wrought’ materials. Hot Isostatic Pressing (HIP) is a process employed to enhance or create materials or products with different mechanical properties by improving density, composition and dynamic strength.

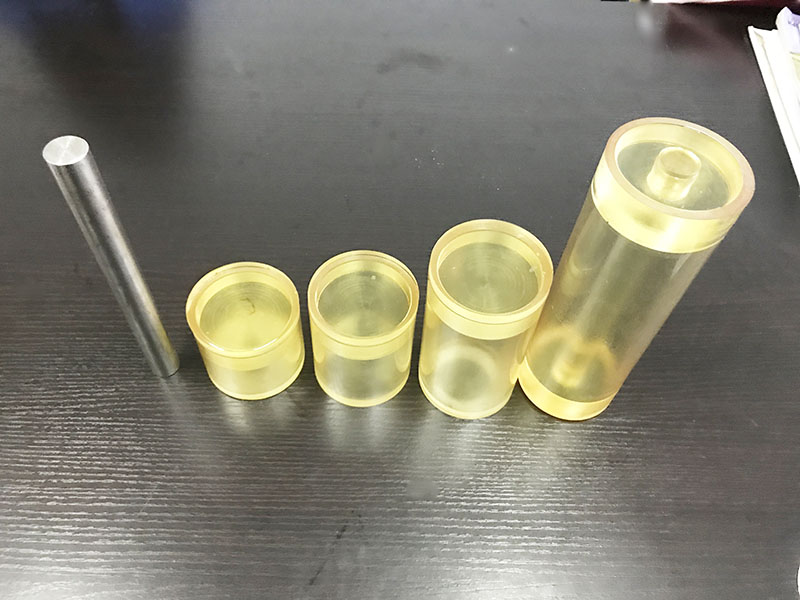

How Does HIP Work?

The definition of ‘isostatic’ (subjected to equal pressure from every side) gives us a fundamental clue to the basic mechanics of HIP.

During Hot Isostatic Presing, pressure is applied to a material uniformly from all directions through an inert gas (such as Argon) in a pressurized vessel. Throughout the process heat is applied to the containment chamber to increase this pressure over time. It is important to note that the temperature employed is typically below the melting point of the material being pressed.

An inert gas is used to ensure that no chemical reaction occurs with the material during the process. The application of both heat and pressure simultaneously on all surfaces of a material helps to eliminate any small gaps (pores) in the material and hence increases density and uniform composition.

HIP in Manufacturing

Typical materials processed by HIP could be:

Ceramics

Metal Powder Castings

Plastics

Hardmetals

Low Carbon Steels

Stainless Steels

Nickel-based Super-alloys

Cobalt-based alloys

Glass

Tungsten Carbide

Applications and Products of HIP

HIP is widely used during the manufacture of high integrity and precise components for a diverse range of applications and industries from Aerospace and Medicine to Automotive.

Composites

Medical Implants

Bi-metal materials

Sintering (Powder metallurgy)

Coatings

Ceramic parts

Metal Matrix Composites

Super-Alloy Castings

Titanium Castings

Gas Turbine Components

Pumps

Valves

Pistons

Cutting Tools

Plastic and food extrusion technology

Heat Treatment

Diffusion Bonding

Redensification

HIP Brazing

Benefits of HIP

HIP allows us to squeeze the impurities (pores) out of materials in order to improve a number of their material characteristics. For example, in sintering (powder metallurgy) the process compresses a volume of metal powder at such high pressures and temperatures, that through a combination of deformation, creep and diffusion bonding you actually create a product with an homogenous annealed microstructure (compact solid) with minimal or no impurities in the material.

HIP gives the manufacturer and ultimate user a number of unique benefits:

Highest Achievable Density

Higher Static Strength

No segregation or grain growth during manufacture

Higher Dynamic / yield and tensile strength

Homogeneous annealed microstructure

Maximum abrasion resistance

Higher Corrosion resistance

Reduced porosity

Improved fatigue resistance

Reduction of Microshrinkage of castings

Near-Net shaped parts

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com